Best practices for shipping and handling wooden furniture

Outline

High-quality packing materials protect wooden furniture during shipping.

Seal boxes securely with reinforced strapping tape for safety.

Corner protectors reduce the risk of damage during transport.

Palletizing provides stability for larger furniture items during shipping.

Clear labels enhance handling care for fragile items.

Proper lifting techniques prevent injury and protect furniture integrity.

Organize small components in labeled bags for easy reassembly.

Inspect furniture for repairs before packing to prevent damage.

Support larger pieces with adequate packing materials during transport.

Communicate handling needs to the shipping company for better care.

Disassemble furniture to minimize shipping risk and damage.

Organize components by size and function for efficient packing.

Utilize climate-controlled containers to protect wooden furniture during transport.

Monitor temperature and humidity levels to prevent wood damage.

Use moisture-resistant packaging to protect furniture from humidity.

Acclimatize furniture to new environments to avoid structural damage.

Insurance safeguards against financial loss during shipping.

Track shipments in real-time to enhance visibility during transport.

Prepare your home and tools before receiving new furniture.

Inspect furniture upon arrival to document possible damage.

Unpack carefully to maintain the integrity of your furniture.

Follow assembly instructions meticulously for optimal functionality.

Recycle packaging materials to promote sustainability after unpacking.

Packing Materials and Techniques

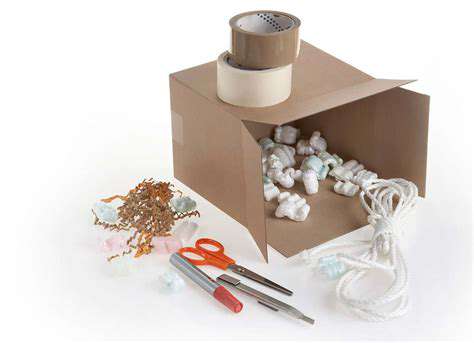

Packing Materials for Shipping Wooden Furniture

When preparing wooden furniture for shipping, selecting the appropriate packing materials is crucial. Using High-quality cardboard boxes can provide a robust layer of protection against dents and scratches. Additionally, foam padding and bubble wrap are effective for cushioning delicate components. This extra layer ensures that the furniture arrives undamaged and maintains its pristine condition during transit. An investment in quality packaging materials reflects in the final delivery experience.

Strapping tape is essential for securely sealing your boxes. It's advisable to use reinforced packing tape instead of standard tape, as it offers greater strength and durability. Make sure to apply multiple strips of tape across seams and openings. Incorporating this simple but effective practice can mean the difference between a secure package and one that falls apart during transport. Remember, thorough sealing is part of ensuring safety for your furniture.

Another important aspect of packing involves using corner protectors or edge guards. These items are particularly useful for fragile areas of the furniture that may chip or crack. By placing these protectors gently on the edges, you can significantly reduce the likelihood of damage throughout the shipping process. Simply put, these additional protective measures are essential to maintaining the integrity of your wooden pieces.

For larger furniture items, consider using palletizing as a shipping technique. This involves placing the furniture on a wooden pallet and securely wrapping it for transport. Palletizing not only provides stability but also makes it easier during the loading and unloading stages. Ensure that the pallet is suitable for the size and weight of your furniture to avoid accidents during handling. Proper palletizing is an effective technique to mitigate risks during shipment.

Lastly, don't overlook the importance of labeling your packages. Clearly marked labels that indicate fragility and orientation can help those handling your shipment take extra care. This step not only improves handling but also minimizes the chance of mishaps. Include any relevant handling instructions to strengthen the awareness regarding the care necessary for your furniture during its journey.

Techniques for Safely Handling Wooden Furniture

When it comes to handling wooden furniture, proper lifting techniques are crucial. Always make sure to bend your knees and keep your back straight to avoid injury when lifting heavy pieces. Engaging your legs while maintaining a stable grip helps to manage the weight effectively. This approach not only protects your body but also maintains the structural integrity of the furniture throughout the process of moving and shipping. Correct lifting techniques ensure a stress-free experience when handling bulky items.

When using tools to disassemble furniture for shipping, it's important to keep track of all nuts, bolts, and screws. Consider placing them in a labeled bag and attaching it to the corresponding furniture piece. This practice not only helps in avoiding losses but also facilitates easier reassembly post-transit. Proper organization is pivotal for a smooth transition from packing to setup in a new location. Keeping all components together minimizes complications.

In addition, take the time to inspect each piece of furniture before packing. Watch for any loose joints or structural weaknesses that could be exacerbated during transport. Making necessary repairs beforehand ensures that the furniture remains in excellent condition throughout shipping. By proactively caring for your items, you're taking an essential step in preventing potential damage. Always prioritize the integrity of your goods to guarantee a satisfactory outcome.

During the packing process, ensure that larger pieces are adequately supported. Utilize packing materials to create a stable structure within the box that prevents shifting. Strapping and padding are essential to hold everything securely in place, ensuring that the furniture does not move during transport. This additional support minimizes the risk of scratches, dents, or other forms of damage. It is fundamental to create a protective barrier that holds your furniture securely.

Finally, maintaining communication with the shipping company is vital. Clearly convey details about the nature of the furniture, along with its handling needs, to the movers. Providing this information allows them to take the necessary precautions during transportation. A good relationship with your shipping provider ensures a greater emphasis on care and handling practices. This communication is key to a successful shipping experience.

Disassembly and Organization

Understanding the Disassembly Process

When preparing wooden furniture for shipping or storage, disassembly is a crucial step that can significantly reduce the risk of damage. This process involves breaking down large items into smaller, more manageable pieces that are easier to handle. Understanding how to properly disassemble each piece of furniture, such as removing legs from tables or separating shelving units, can ensure that the item maintains its structural integrity throughout the journey.

Before starting the disassembly process, it’s important to have the right tools on hand, which may include screwdrivers, wrenches, and pliers. Additionally, a soft cloth or protective padding helps prevent scratches and dents. Always take the time to document the steps taken, either through photographs or notes, so that reassembly at the destination can be straightforward and stress-free. Keeping track of screws and small components in labeled bags can ensure that nothing is lost.

In some cases, you may also want to consult the manufacturer’s instructions for specific disassembly guidelines, especially for complex items. Ensuring that you follow these instructions can minimize the risk of damaging the furniture or voiding any warranties. The disassembly process is not just about convenience; it's a proactive way to safeguard the quality of wooden furniture during transit.

Organizing and Packing the Disassembled Parts

Once the furniture is disassembled, organizing the parts is essential for efficient packing and transportation. Start by categorizing each component based on its size and function. This organization not only makes packing easier but also helps ensure that everyone involved in the move understands where to find each piece. For instance, keeping all screws and small hardware neatly labeled in a bag can prevent confusion and avoid any mishaps during reassembly.

Next, utilize high-quality packing materials to protect the disassembled parts. Bubble wrap, packing paper, and foam cushioning are excellent choices for wrapping delicate pieces. Each part should be wrapped securely to guard against scratches and impact damage during transit. It’s also advisable to create a packing list that includes every item being shipped, as this will help manage inventory and confirm that nothing has been overlooked before the furniture is loaded onto the truck.

Lastly, don’t hesitate to seek assistance from professionals if the furniture is particularly valuable or intricate. Experts can provide insight into the safest packing methods and may also use specialized materials that offer the best protection. By taking the time to properly organize and pack disassembled furniture, shippers can ensure a smoother transition to its new location, preserving both aesthetics and functionality.

Climate Considerations

Understanding the Impact of Climate on Wooden Furniture

Wood is a natural material that is greatly influenced by environmental conditions. Changes in temperature and humidity can cause wood to expand or contract, leading to potential damage. It’s essential for shippers and handlers to understand the climate conditions of both the origin and destination locations when dealing with wooden furniture, as this can significantly impact the integrity of the products being transported.

Different types of wood react uniquely to climatic variations. For instance, tropical hardwoods may withstand humidity better than softer woods used in typical home furnishings. Being knowledgeable about the specific characteristics of the wood can help in making more informed decisions regarding packaging and transport methods, ensuring that the final product reaches the consumer in prime condition.

Moreover, climate-related issues, such as excessive moisture or extreme heat, can lead not only to physical alterations but also to structural weaknesses over time. Furniture that is subjected to erratic climate shifts during shipping risks developing warping, cracking, or surface blemishes that compromise both aesthetic appeal and functionality.

Best Practices for Climate-Controlled Shipping

Utilizing climate-controlled shipping containers is critical for transporting wooden furniture effectively. These specialized containers help maintain a stable internal environment, preventing harmful fluctuations that could adversely affect the wooden materials. Implementing this practice is particularly vital for high-value or sensitive items, where ensuring quality during transit is paramount.

It is equally important for shippers to monitor and record temperature and humidity levels throughout the journey. Advanced tracking systems can alert handlers to any environmental changes that might occur, enabling them to take swift and decisive actions to mitigate potential damage. This proactive approach can save both the shipper and the customer from costly loss and dissatisfaction.

Additionally, positioning furniture correctly within the container can further protect it from climate extremes. For instance, placing heavier items on the bottom can help stabilize the load, while ensuring that there’s ample ventilation can aid in maintaining proper humidity levels, crucial for protecting the integrity and finish of wooden pieces.

Packaging Strategies for Environmental Protection

Effective packaging is essential for safeguarding wooden furniture during transportation. Using moisture-resistant materials can provide a critical layer of protection against unexpected humidity that may develop in transit. Layering in cushioning materials like bubble wrap or foam can also prevent physical impacts while maintaining ventilation around the furniture.

Incorporating desiccants within your packaging can additionally absorb excess moisture, creating a more stable environment for wooden items. This should be considered particularly during humid seasons or when shipping to warmer climates, where the risk of deterioration due to moisture is heightened.

Labeling packages with clear handling instructions can further enhance protection. It ensures that all personnel involved in the packing, loading, and transporting processes are aware of the specific needs of wooden furniture, promoting greater care and vigilance, and ultimately prolonging the lifespan of the items shipped.

Acclimatization: An Often-Overlooked Step

Acclimatization refers to the practice of allowing wooden furniture to adjust to new environmental conditions before final placement in homes or offices. Following transport, it's crucial to let the items sit in their new environment for a period, which allows them to acclimate to local temperature and humidity levels. This step is often overlooked but can prevent extensive structural damage and cosmetic issues.

During the acclimatization phase, furniture should be kept in a controlled environment, ideally matching the expected final destination conditions. This not only enhances the stability of the wood but also facilitates any necessary adjustments to the furniture before it's utilized, leading to better satisfaction for the end-user.

Communicating the importance of acclimatization to customers can significantly improve their experience. Providing guidelines on how long to wait and what conditions to maintain can empower customers to take proactive steps, ensuring that their new furniture stays in excellent shape for many years.

Long-Term Climate Considerations for Wooden Furniture Care

Long-term care of wooden furniture requires constant vigilance regarding climatic conditions. Homeowners should be educated on maintaining stable humidity and temperature levels within their living spaces. Ideally, indoor humidity should be kept between 30% and 50% to enhance wood's longevity and structural integrity.

Additionally, encourage routine maintenance practices such as regular dusting and polishing, which not only enhance aesthetics but also create a protective barrier against environmental stressors. Developing and sharing a maintenance schedule can assist consumers in taking thoughtful care of their wooden pieces, minimizing excess wear and tear.

It is also beneficial to educate consumers about signs of climate-related damage such as cracks or warping. This knowledge can alert them to take preventive action or seek professional restoration services when necessary, ensuring that their investment is protected for years to come.

Insurance and Tracking

Understanding the Importance of Insurance in Shipping Wooden Furniture

When shipping wooden furniture, insurance serves as a critical safeguard against potential losses. Each piece crafted from unique materials can hold significant value, and protecting that investment is vital for any business or individual. Without proper insurance coverage, the risk of financial loss due to damage, theft, or unforeseen events becomes a considerable concern.

Moreover, insurance can provide peace of mind during the shipping process. When you know that your valuable wooden furniture is insured, you can focus on other aspects of the shipping process. This not only simplifies your logistics but also enhances overall confidence in the quality of service you’re providing.

Tracking Shipments: Enhancing Visibility and Control

The implementation of tracking technology has revolutionized how we manage shipping logistics, especially for delicate items like wooden furniture. With real-time tracking, both shippers and customers can monitor the location of their shipments throughout the entire transit process. This level of visibility ensures that all parties are informed and can respond promptly to any unexpected issues.

Additionally, tracking provides an essential layer of customer service. Customers appreciate the ability to see where their furniture is at any moment, which builds trust and satisfaction. Keeping clients informed about their shipments can lead to repeat business and positive referrals, which are invaluable in a competitive market.

Best Practices for Combining Insurance and Tracking

To maximize the effectiveness of shipping wooden furniture, integrating insurance with reliable tracking systems is imperative. When both are utilized together, it creates a comprehensive safety net that significantly mitigates risks. Establishing clear communication with the insurance provider about tracking responses can help address issues swiftly and efficiently.

Regularly updating clients about their shipments and insurance coverage reinforces a culture of transparency. It is advisable to provide clients with all relevant tracking information and details about their insurance policy upfront. This proactive approach not only clears up confusion but also helps in establishing a strong relationship built on trust and reliability.

Receiving and Unpacking

Preparing for Receipt

Before the furniture arrives, it's essential to ensure your space is adequately prepared to receive it. This includes clearing ample space in your home for the new pieces and making sure the pathway from the entrance to the designated area is unobstructed. This preparation not only makes the unpacking process smoother but also protects both the furniture and your home from potential damage.

Additionally, gather the necessary tools, such as a screwdriver, box cutter, and packing tape, to facilitate the unpacking process. Having the right tools at hand will save you time and energy, ensuring a quick and efficient setup. A well-prepared environment reflects a level of care towards your new investment.

Inspection Upon Arrival

Once your wooden furniture arrives, inspecting it thoroughly is crucial. Check for any visible damage, such as scratches, dents, or missing components, while the delivery personnel are still present. Documenting any issues immediately can help streamline communication with your supplier should any claims need to be addressed.

If any problems are detected, don't hesitate to report them right away. Taking photographs and noting details can provide necessary evidence should disputes arise later. Quick action ensures you are not left with unsatisfactory items.

Unpacking Methods

Careful unpacking is necessary to maintain the integrity of your furniture. Use appropriate tools to cut away packaging without damaging the wood. For instance, avoid using sharp objects too close to the surface of the items. Taking your time during this stage can prevent costly mistakes.

Consider unpacking in stages; start with the larger, bulkier items and follow with smaller components. This methodical approach reduces the likelihood of feeling overwhelmed and helps in systematically organizing the pieces. Remember, patience is key when handling exquisite wooden furniture.

Product Assembly Guidelines

Once unpacked, follow the manufacturer's assembly instructions meticulously. Review the assembly manual before beginning to ensure you understand how each piece fits together. Proper assembly is vital for the functionality and longevity of your furniture.

If any additional tools are required for assembly, make sure to have them ready beforehand. Rushing this process can lead to misalignment or structural issues that could compromise the piece's durability. Always prioritize doing it right the first time.

Disposal of Packaging Materials

After unpacking and assembling your furniture, it's important to responsibly dispose of the packaging materials. Cardboard, plastic, and Styrofoam can often be recycled, so ensure they are sorted correctly for disposal. This not only helps the environment but also keeps your space tidy.

Consider reusing some materials for future moving or storage needs, which can be beneficial and cost-effective. Maintaining a clean environment post-unpacking will enhance your enjoyment of the new furniture and demonstrates a commitment to sustainability.