How to choose a wooden chair for maximum comfort

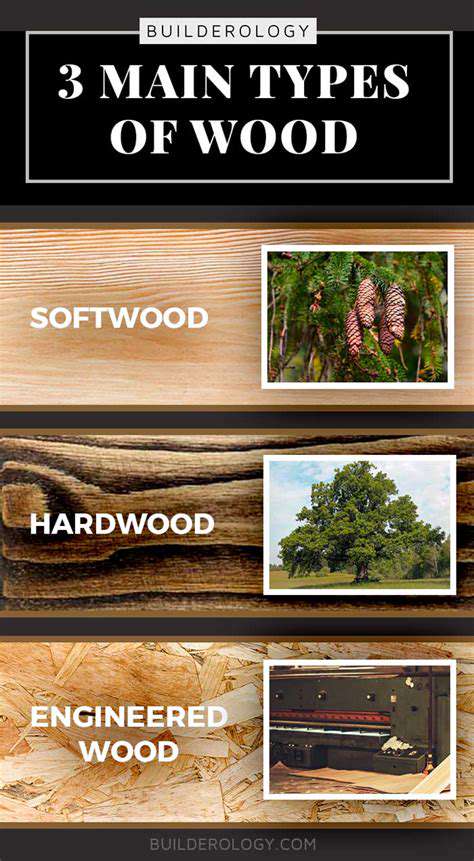

Exploring Different Wood Types and Their Attributes

Exploring Hardwoods

When it comes to furniture craftsmanship, hardwoods from deciduous trees remain the gold standard. Their legendary durability and structural integrity make them the preferred material for heirloom-quality pieces. Each species tells its own story through distinctive characteristics - cherry wood develops a richer patina over time, while oak's prominent grain patterns showcase nature's artistry. Woodworkers particularly value hardwoods for their dimensional stability and resistance to wear, ensuring generations of use.

The Janka hardness scale provides crucial insights for material selection. A wood's rating directly correlates with its ability to withstand daily wear and tear. For instance, hard maple (1,450 lbf) excels in high-traffic flooring applications, while black walnut (1,010 lbf) offers the perfect balance between workability and durability for fine furniture. This scientific approach to material selection helps craftsmen match wood properties to functional requirements.

Understanding Softwoods

Coniferous softwoods play a vital role in both construction and design. While often perceived as inferior to hardwoods, species like Douglas fir and Southern yellow pine offer exceptional strength-to-weight ratios. Their cellular structure makes them ideal for engineered wood products, with dimensional stability that outperforms many hardwoods in certain applications. The construction industry particularly values softwoods for their consistent quality and predictable performance.

Modern forestry practices have transformed softwood availability. Sustainable plantation growth ensures a reliable supply of these versatile materials. From structural framing to intricate millwork, softwoods continue to demonstrate their adaptability. Their natural resin content provides built-in protection against moisture, making them surprisingly durable for exterior applications when properly treated.

Analyzing Wood Grain Patterns

The visual poetry of wood grain transforms functional objects into works of art. Each species presents unique figure variations - quarter-sawn oak displays dramatic ray flecks, while curly maple creates mesmerizing three-dimensional effects. These natural patterns become the designer's palette, influencing everything from furniture orientation to finish selection. The interplay between grain direction and light reflection adds dynamic visual interest to wooden surfaces.

Understanding grain behavior is essential for woodworkers. Proper orientation affects both aesthetics and structural integrity. Bookmatching consecutive veneer slices creates mirror-image symmetry, while rift-cutting minimizes grain pattern for a more uniform appearance. These techniques allow craftsmen to highlight or subdue wood's natural character based on design intent.

Examining Wood Density and Strength

Material science reveals why wood density matters. The relationship between cellular structure and mechanical properties determines a wood's suitability for specific loads. Tropical hardwoods like ipe (3,680 lbf Janka) demonstrate how extreme density creates nearly indestructible decking material. Conversely, lightweight basswood (410 lbf) serves perfectly for intricate carvings where easy workability trumps structural demands.

Moisture content dramatically impacts wood performance. Properly dried lumber (6-8% moisture content for interior use) maintains dimensional stability, while green wood continues to move as it seasons. This understanding informs everything from joinery techniques to finishing schedules, ensuring long-term performance matches initial expectations.

Considering Wood Durability and Maintenance

Natural durability varies remarkably between species. While white oak's tyloses make it exceptionally rot-resistant, other woods require protective treatments for outdoor use. The key lies in matching material properties to environmental conditions. Teak's natural oils provide built-in weather resistance, explaining its maritime applications, while cedar's aromatic compounds deter insect damage without chemical treatment.

Modern finishing technologies have revolutionized wood maintenance. Advanced UV-resistant coatings protect against solar degradation, while penetrating oils enhance natural beauty without creating surface films. Proper product selection can triple a wood's service life, making maintenance considerations as important as initial material choice.

Considering the Style and Design of the Chair

Evaluating the Chair's Aesthetics

Furniture design creates visual conversations within a space. When selecting a wooden chair, consider how its design language communicates with your existing decor. A successful piece should neither dominate nor disappear in its environment. The chair's silhouette - whether Shaker simplicity or Chippendale ornamentation - establishes its stylistic era. Finish choices further refine this dialogue, with dark stains conveying formality while natural finishes suggest casual warmth.

Details separate ordinary chairs from extraordinary ones. Look for thoughtful touches like hand-cut dovetails or subtly radiused edges that reveal the maker's dedication. These subtle refinements often indicate superior craftsmanship throughout the piece. Consider how decorative elements like turned legs or carved aprons contribute to the overall design narrative.

Assessing the Chair's Construction

Quality construction reveals itself in the details. Examine joinery - traditional mortise-and-tenon joints indicate serious craftsmanship, while doweled construction suggests cost-conscious manufacturing. Solid wood components should show continuous grain patterns, proving they're not finger-jointed from smaller pieces. Check underside surfaces; quality manufacturers finish these areas as carefully as visible surfaces.

Structural integrity begins with material selection. Look for quarter-sawn wood in critical areas - its stability prevents seasonal movement issues. Proper grain orientation in legs and rails prevents future weakness. Test the chair's rigidity by applying gentle torsion; quality construction will feel solid without creaking or flexing.

Understanding the Chair's Comfort

Ergonomics transform furniture from decorative to functional. A well-designed wooden chair considers human proportions - seat height (typically 17-19) affects leg comfort, while backrest angle (100-110 degrees) supports proper posture. Subtle contours make surprising comfort differences; even a slight saddle-shaped seat improves circulation during extended sitting.

Consider usage patterns. Dining chairs need different support than occasional seating. Look for features like waterfall seat edges that reduce leg pressure or lumbar-supporting back splats. These thoughtful details separate mass-produced chairs from designs that truly understand human anatomy.

Analyzing the Chair's Durability

Longevity depends on both materials and construction. Hardwood species with tight grain patterns withstand years of use better than porous woods. Finish quality proves equally important - look for catalyzed varnishes on quality pieces rather than simple lacquers. Check wear points like armrests and front seat edges for extra thickness or protective treatments.

Stress points reveal construction quality. Examine where legs meet seats - reinforced corner blocks indicate serious construction. Look for continuous wood grain running through curved elements rather than laminated sections that may separate over time. These features predict how well a chair will age with regular use.

Considering the Chair's Overall Size and Proportion

Scale creates visual harmony. Before purchasing, tape out the chair's footprint on your floor. Leave adequate clearance space (at least 36) for comfortable circulation. Consider sight lines - a chair's height shouldn't block important views or architectural features. Proportion matters equally; seat depth should accommodate various body types without appearing oversized.

Visual weight affects perception. Dark finishes make chairs appear more substantial, while light woods create airy impressions. Spindle-back designs offer visual transparency, helping small spaces feel more open. These subtle factors influence how furniture integrates with your existing layout.

Comparing Prices and Value

True value extends beyond price tags. Consider cost-per-year by estimating the chair's lifespan - a $1,000 chair lasting decades often proves wiser than replacing $200 chairs every few years. Handcrafted pieces typically appreciate, while mass-produced furniture depreciates. Look for hallmarks of quality like solid wood construction (no veneers over particleboard) and traditional joinery techniques.

Manufacturer reputation offers important clues. Companies with decades of experience typically refine their designs through continuous improvement. Warranty terms reveal confidence in durability - quality manufacturers often guarantee frames for life. These factors help identify chairs that represent genuine value rather than just attractive pricing.

- Affordable ways to upgrade your home with wooden furniture

- The process of crafting bespoke wooden furniture

- Top rated wooden furniture for home offices

- How to choose the perfect wooden bed frame for your bedroom

- How to select wooden furniture for your modern home

- Why wooden furniture is better for your health and well being

- How to create a home office with stylish wooden furniture

- How to incorporate wooden furniture into your farmhouse kitchen

- How to find wooden furniture that fits your space and style

- How to use wooden furniture in a small space effectively

- How to care for and protect wooden furniture in high humidity areas

- How to decorate your living room with light wood furniture