How to restore and refinish your antique wooden furniture

Evaluating the Condition of the Wood

Wood behaves like a living material, responding to environmental changes long after harvesting. Seasonal expansion and contraction leave telltale signs in antique specimens. When assessing:1. Run your fingertips across surfaces to detect: - Raised grain patterns - Unexpected softness in localized areas - Temperature variations that might indicate moisture retention2. Examine end grains for: - Radial cracks from drying stresses - Evidence of previous insect activity (exit holes without fresh frass)Professional restorers often use dental mirrors to inspect hidden cavities where problems frequently originate undetected.

Assessing the Finish

Original finishes represent historical artifacts themselves, containing clues about:- Period-correct application techniques- Regional manufacturing practices- Previous restoration attemptsUltraviolet light examination can reveal undocumented repairs through fluorescence variations. When documenting finish conditions:- Photograph under multiple light angles- Note areas where wear patterns align with typical usage- Distinguish between intentional distressing and authentic agingConservators recommend maintaining at least 70% original finish to preserve collector value.

Identifying the Type of Wood

Wood identification requires examining multiple characteristics:

| Feature | Examination Technique |

|---|---|

| Pore structure | 10x magnification of cross-sections |

| Medullary rays | Quarter-sawn surface inspection |

| Odor profile | Light sanding of hidden area |

Considering the Furniture's History

Provenance research should examine:- Construction methods (hand-cut dovetails vs. early machine joinery)- Fastener types (cut nails indicate pre-1890s manufacture)- Tool marks (planer patterns reveal technological eras)Local historical societies often maintain records of regional cabinetmakers that can authenticate unsigned pieces. Always check for:- Estate sale tags affixed to undersurfaces- Shipping labels in hidden compartments- Period modifications reflecting changing domestic needs

Cleaning and Repairing the Furniture

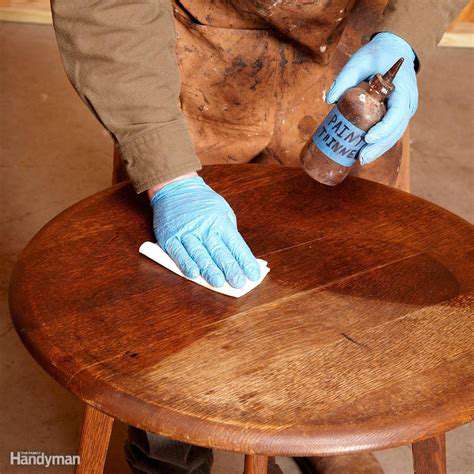

Cleaning Strategies for Furniture

Surface preparation precedes any restoration work. Conservators employ the minimum intervention principle, using:- Dry methods (soft brushes, microfiber) before liquids- pH-neutral solutions tested in inconspicuous areas- Cotton swabs for precise applicationAvoid modern cleaning products containing:✗ Silicones that create artificial shine✗ Petroleum distillates that degrade old finishes✗ Abrasives that remove patina

Repairing Damage to Wood Furniture

Traditional repair techniques include:- Hot hide glue for reversible joints- Dutchman patches for missing wood- Shellac sticks for fill repairsContemporary epoxies should only be used when reversibility isn't required. For structural repairs:1. Disassemble only as needed2. Document original configurations3. Preserve original tool marks4. Use period-appropriate materials

Addressing Upholstery Damage and Tears

Historic upholstery conservation involves:- Photographing original stuffing layers- Preserving fabric samples for dye matching- Using traditional tacks instead of staplesOriginal springs often require re-tying with hand-twisted jute. When reupholstering:- Maintain original stuffing profiles- Replicate period stitching patterns- Source appropriate reproduction fabrics

Restoring Metal and Glass Furniture

Metal components require:- Electrolytic reduction for iron corrosion- Mechanical cleaning for brass elements- Wax protection after treatmentGlass preservation focuses on:- Edge stabilization for aged glass- UV-filtering films for protection- Silicone mounting for stress reduction

Combustion byproducts affect more than engines. Historic finishes undergo molecular changes from environmental exposure, creating complex conservation challenges. The parallel between carbon deposits and finish degradation lies in their cumulative nature - both represent the unavoidable consequences of material interactions with their environments over time.