Simulating Supply Chain Scenarios: AI for Advanced Planning

Optimizing Inventory Management and Resource Allocation

Understanding Inventory Management Dynamics

Effective inventory management is crucial for a smooth-running supply chain, directly impacting profitability and customer satisfaction. A deep understanding of inventory dynamics, including lead times, demand fluctuations, and safety stock levels, is paramount. This involves analyzing historical data, forecasting future demand, and implementing strategies to minimize holding costs while ensuring sufficient stock to meet customer orders. Accurate forecasting models and robust inventory tracking systems are essential for optimizing these dynamics and avoiding costly stockouts or excessive inventory.

Inventory levels need to be carefully balanced. Too much inventory ties up capital that could be used elsewhere, leading to increased storage costs, obsolescence risks, and potential damage or deterioration. Conversely, inadequate inventory can result in lost sales, unhappy customers, and disrupted production schedules. Finding the optimal balance requires a thorough understanding of the interplay between demand, supply, and lead times.

Resource Allocation Strategies for Efficiency

Efficient resource allocation is vital for optimizing supply chains. This involves assigning resources like labor, equipment, and materials strategically across different stages of production and distribution. The goal is to ensure optimal utilization of resources while minimizing waste and maximizing output. This requires careful planning and execution, taking into account factors such as production capacity, transportation networks, and material availability.

Effective resource allocation strategies must also consider the variability and uncertainty inherent in supply chains. Unforeseen events, such as natural disasters or unexpected supplier delays, can disrupt operations. Therefore, robust contingency plans and flexible resource allocation strategies are essential for mitigating the impact of these disruptions and maintaining smooth operations.

Simulating Demand and Supply Fluctuations

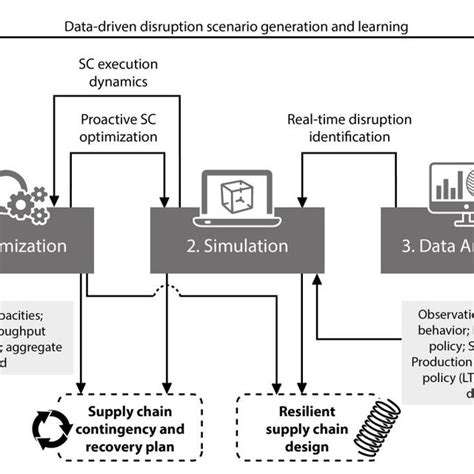

Simulating scenarios is a powerful tool for assessing the impact of demand and supply fluctuations on inventory levels and resource allocation. By creating virtual models of the supply chain, businesses can test different strategies and anticipate potential problems before they arise. These simulations help identify bottlenecks, predict potential shortages or surpluses, and evaluate the effectiveness of different mitigation strategies.

Supply chain simulations allow for a more thorough understanding of the system. This enables adjustments in the resource allocation strategy and inventory management to prepare for different future outcomes. Testing various scenarios allows companies to anticipate and respond to disruptions in the supply chain, making them more resilient and adaptable to changing conditions.

Utilizing Data Analytics for Informed Decision-Making

Data analytics plays a critical role in optimizing inventory management and resource allocation. By analyzing historical data on sales, production, and logistics, businesses can identify patterns, predict future trends, and make data-driven decisions. This involves utilizing various analytical techniques such as statistical modeling, machine learning, and predictive analytics.

Comprehensive data analysis allows businesses to develop more accurate forecasts, optimize inventory levels, and allocate resources more effectively. Analyzing data from various sources, including sales figures, production records, and supplier data, provides valuable insights into the behavior of the supply chain. This information can be used to refine forecasting models and improve decision-making processes.

Implementing Agile and Adaptive Strategies

In today's dynamic business environment, agile and adaptive strategies are crucial for optimizing inventory management and resource allocation. This involves embracing flexibility and responsiveness to changes in demand, supply, and market conditions. Companies must be able to adjust their strategies quickly and efficiently to minimize disruptions and maintain a competitive advantage.

Implementing agile strategies requires a culture of collaboration and communication throughout the supply chain. Regular communication and collaboration between different departments, suppliers, and customers are vital for ensuring that everyone is aware of any changes and can adapt accordingly. This fosters a shared understanding of the supply chain's current state and enables proactive responses to unforeseen events or shifting market demands.

Measuring and Monitoring Performance Metrics

Effective inventory management and resource allocation require continuous monitoring and evaluation of performance metrics. Establishing key performance indicators (KPIs) is essential for tracking progress and identifying areas for improvement. Metrics such as inventory turnover rate, stockout frequency, and resource utilization rate provide valuable insights into the efficiency of the supply chain.

Regularly analyzing these metrics allows companies to identify bottlenecks, inefficiencies, and areas where improvements can be made. Monitoring performance metrics provides a clear picture of the supply chain's health and allows for timely interventions to maintain optimal performance. This data-driven approach ensures that strategies remain aligned with the company's overall goals and objectives.

- Best multi functional wooden furniture for compact spaces

- Best wooden furniture for apartments with small spaces

- How to mix wooden furniture with metal elements in interior design

- Best wooden furniture brands for durability and style

- How to select the best wooden chairs for your dining room

- How to style your bedroom with wooden furniture accents

- Best wooden furniture for small apartments and condos

- How to decorate your home with elegant wooden furniture

- How to create a stylish living room with wooden furniture accents

- AI Powered Visual Inspection for Quality Control

- Data Sharing Best Practices for Supply Chain Visibility

- The Role of Big Data in Supply Chain Network Optimization