Au-delà des limites humaines : L'avenir de la manutention robotisée des matériaux

Révolutionner le transport

Les véhicules autonomes, des camions sans conducteur aux drones de livraison, transforment rapidement le paysage logistique. Ces véhicules offrent un potentiel important d'augmentation de l'efficacité et de réduction des coûts en optimisant les itinéraires, en minimisant les temps d'arrêt et en garantissant des délais de livraison constants. L'intégration

Au-delà de la préhension et la pose : Développer les capacités robotiques

Au-delà des bases : Robots multitâches

Les robots de préhension et de pose, bien que précieux dans leurs applications spécifiques, sont souvent limités dans leur utilité globale. Développer les capacités robotiques signifie aller au-delà de la simple manipulation d'objets pour

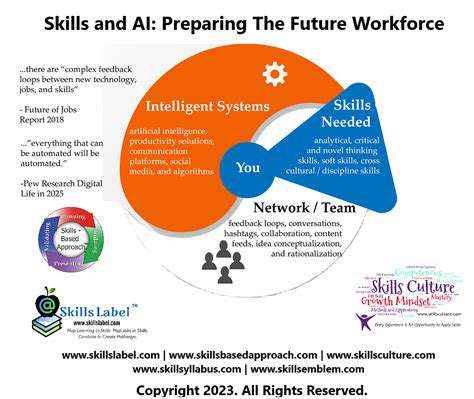

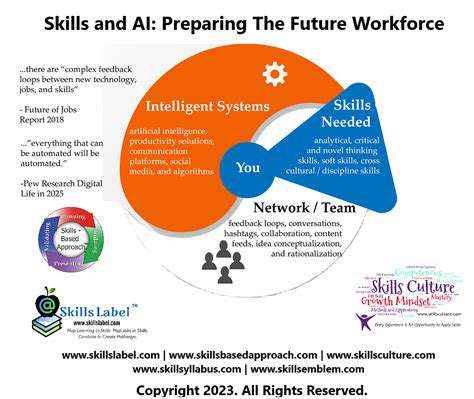

L'impact sur la main-d'œuvre et le développement des compétences

Évolution des besoins en compétences dans le lieu de travail moderne

More about Au-delà des limites humaines : L'avenir de la manutention robotisée des matériaux