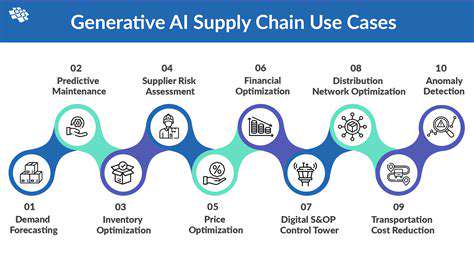

IA générative pour l'identification des problèmes de chaîne d'approvisionnement

Predictive Modeling for Risk Mitigation

Predictive Modeling Techniques

Predictive modeling, a cornerstone of risk mitigation strategies, leverages historical data to anticipate future events and potential risks. By identifying patterns and relationships within data, predictive models can forecast the likelihood of various outcomes, enabling proactive measures to minimize negative impacts. This approach is particularly valuable in scenarios where immediate responses to unexpected events are crucial, allowing for preventative action instead of reactive measures.

Various statistical and machine learning techniques form the foundation of predictive modeling. These methods range from simple linear regressions to sophisticated algorithms like neural networks and support vector machines. The choice of technique often depends on the nature of the data, the complexity of the relationships being modeled, and the specific risk being assessed.

Data Preparation and Feature Engineering

Accurate predictive models are heavily reliant on the quality and preparation of the input data. Cleaning and transforming the data to ensure consistency, accuracy, and relevance is crucial. This process involves handling missing values, addressing outliers, and potentially transforming variables to improve model performance. Careful consideration must be given to the potential biases present in the data, which can skew results and ultimately affect the effectiveness of the risk mitigation strategies.

Feature engineering, the process of creating new variables from existing ones, is another critical step in data preparation. By identifying and extracting relevant information from the data, we can improve the model's ability to identify patterns and relationships associated with the risk. For example, creating composite indicators from various factors can provide a more nuanced understanding of the risk profile.

Careful consideration of data quality and appropriate feature engineering are critical to building a reliable predictive model.

Model Evaluation and Validation

Model evaluation is essential to ensure the model's accuracy and reliability in predicting future events. Various metrics, such as precision, recall, and F1-score, are used to assess the model's performance on unseen data. This evaluation process is crucial to ensure that the model is not overfitting to the training data, a common pitfall in predictive modeling. Overfitting occurs when a model learns the training data too well, leading to poor performance on new, unseen data.

Rigorous validation is paramount to building confidence in the predictive model's ability to accurately reflect real-world scenarios. Techniques like cross-validation are employed to assess the model's robustness and generalizability. By testing the model on multiple subsets of the data, we can gain a more comprehensive understanding of its predictive power and identify potential weaknesses. This process helps ensure the model's suitability for real-world applications in risk mitigation.

Ultimately, a thorough evaluation and validation process is vital for developing a reliable and effective predictive model for risk mitigation.

Automated Anomaly Detection and Root Cause Analysis

Leveraging Generative AI for Anomaly Detection

Generative AI models, trained on historical supply chain data, can identify anomalies that traditional methods might miss. These models learn the normal patterns of order fulfillment, inventory levels, and transportation routes. When deviations occur, the model flags them as potential issues, allowing for proactive intervention and preventing disruptions. This capability is crucial for maintaining a resilient and efficient supply chain, as unexpected events can have cascading effects.

By analyzing vast datasets, generative AI can uncover subtle patterns and relationships that might not be apparent to human analysts. This allows for early detection of anomalies, potentially preventing significant financial losses and operational inefficiencies. The ability to predict potential issues empowers companies to make informed decisions and adapt to changing circumstances, ultimately leading to a more agile and adaptable supply chain.

Root Cause Analysis with Enhanced Insights

Beyond simply identifying anomalies, generative AI can delve deeper to pinpoint the root causes. By analyzing the context surrounding detected anomalies, such as specific supplier performance, weather patterns, or geopolitical events, the AI can provide insights into the underlying factors driving the issue. This detailed analysis is invaluable for taking corrective action and preventing future occurrences.

This level of analysis is often beyond the capacity of manual methods, which can struggle to correlate disparate data points. Generative AI excels at this, allowing for a more comprehensive understanding of complex supply chain issues. This deeper understanding empowers companies to implement targeted solutions, minimizing the impact of disruptions and maximizing operational efficiency.

Predictive Modeling for Proactive Measures

Generative AI can be used to create predictive models that forecast potential future anomalies. By analyzing historical data and current trends, the AI can identify patterns that suggest a potential disruption, such as a sudden surge in demand, a supplier shortage, or a logistical bottleneck. This allows companies to proactively implement mitigation strategies before the issue significantly impacts operations.

These predictive models are crucial for maintaining a resilient supply chain. They enable proactive measures, reducing the risk of unforeseen events and allowing companies to adapt more effectively to dynamic market conditions. This ultimately translates to better inventory management, optimized transportation, and minimized downtime.

Improved Decision-Making and Resource Allocation

The insights generated by generative AI can significantly improve decision-making within the supply chain. By providing clear and actionable recommendations, AI can help stakeholders make informed choices related to resource allocation, inventory management, and logistics. This data-driven approach leads to optimized resource utilization and minimizes operational costs.

Enhanced Collaboration and Communication

Generative AI facilitates seamless communication and collaboration among different departments and stakeholders involved in the supply chain. By providing a unified platform for accessing and analyzing data, AI fosters greater transparency and shared understanding. This enhanced collaboration improves response times to emerging issues and streamlines problem-solving processes.

The improved communication fostered by AI allows for quicker identification and resolution of problems, minimizing the impact on the overall supply chain. This collaborative environment creates a more resilient and efficient supply chain, where everyone is working towards a common goal.

Optimizing Inventory Management and Resource Allocation

Improving Inventory Accuracy with Generative AI

Generative AI models can analyze historical sales data, predict future demand fluctuations, and identify potential stockouts or overstocking scenarios with remarkable accuracy. By learning patterns and trends in sales data, these models can provide more precise inventory forecasts, reducing the need for manual adjustments and minimizing the risk of costly inventory discrepancies. This leads to improved inventory turnover rates and reduced carrying costs, ultimately optimizing resource allocation within the supply chain.

Predictive capabilities of generative AI extend beyond simple forecasts. They can identify anomalies in sales patterns, potentially signaling issues like shifts in customer preferences or unexpected product demand surges. This proactive approach allows businesses to adjust inventory levels and resource allocation in real-time, ensuring they're always prepared for evolving market conditions.

Dynamic Resource Allocation for Enhanced Efficiency

Generative AI empowers companies to dynamically allocate resources across various stages of the supply chain. By simulating different scenarios and considering factors like transportation costs, lead times, and production capacity, AI can optimize routes, delivery schedules, and production plans, leading to significant cost savings and improved efficiency.

This dynamic resource allocation extends beyond simple logistics. AI can analyze the entire supply chain network, identifying bottlenecks and inefficiencies in real-time. This allows for proactive adjustments to production plans, workforce scheduling, and material procurement, ensuring a seamless flow of goods and services.

Predictive Maintenance and Equipment Optimization

Generative AI can analyze equipment performance data, predict potential failures, and optimize maintenance schedules. This proactive approach minimizes downtime, reduces repair costs, and maximizes equipment lifespan. By learning patterns in equipment performance, the AI can identify subtle indicators of impending issues, allowing for preventative maintenance before significant breakdowns occur.

The insights gained from generative AI in predictive maintenance extend beyond equipment optimization. They can also inform decisions regarding the procurement of new equipment, replacement cycles, and potential investment in upgrading existing infrastructure, thereby maximizing the overall return on investment.

Demand Forecasting and Demand-Driven Inventory

Generative AI excels at demand forecasting, enabling businesses to predict future customer demand with greater accuracy. This empowers companies to maintain optimal inventory levels, reducing waste and ensuring products are readily available when needed. By considering factors like seasonality, promotional campaigns, and market trends, generative models provide more comprehensive and reliable demand forecasts.

The demand-driven inventory approach made possible by generative AI goes beyond simple forecasting. It allows companies to optimize their inventory strategies in real time, adjusting levels based on immediate demand spikes or dips. This responsiveness to real-world conditions minimizes storage costs and maximizes profitability.

Optimizing Transportation and Logistics

Generative AI can optimize transportation routes and schedules, considering factors like traffic conditions, fuel costs, and delivery deadlines. This leads to reduced transportation expenses, faster delivery times, and improved overall logistics efficiency. By learning from historical data and real-time information, AI algorithms can dynamically adjust routes and schedules, avoiding congestion and optimizing delivery times.

Furthermore, generative AI can identify potential disruptions in the transportation network, such as weather-related delays or unexpected traffic incidents. This proactive approach allows companies to make timely adjustments to their logistics plans, minimizing potential delays and ensuring goods reach their destinations on time.

Improved Customer Service and Fulfillment

Generative AI enhances customer service by automating tasks like order processing, answering customer inquiries, and resolving issues. This frees up human resources to focus on more complex tasks, improving customer satisfaction. By analyzing customer data and preferences, AI can personalize recommendations and improve the overall customer experience.

Furthermore, the ability of generative AI to predict demand and optimize inventory levels translates directly to improved order fulfillment. Companies can ensure that customer orders are processed and shipped efficiently, leading to faster delivery times and increased customer satisfaction. This direct impact on order fulfillment enhances the overall customer experience.

Enhanced Supply Chain Visibility and Collaboration

Generative AI provides enhanced visibility into the entire supply chain, allowing businesses to track goods and materials in real-time. This transparency enables better communication and collaboration among different stakeholders, fostering greater efficiency and responsiveness. By analyzing data from various sources, AI can provide a comprehensive view of the supply chain, highlighting potential bottlenecks, delays, and other critical issues.

The improved visibility provided by generative AI also facilitates better collaboration among suppliers, manufacturers, and distributors. This collaborative approach helps to streamline processes, reduce lead times, and enhance the responsiveness of the entire supply chain network to changing market conditions.

Improving Collaboration and Communication Across the Supply Chain

Establishing Clear Communication Channels

Effective collaboration hinges on clear and consistent communication. Defining specific communication channels, whether email, instant messaging, project management software, or dedicated team meetings, is crucial for ensuring everyone is kept informed and on the same page. This clarity prevents misunderstandings and fosters a sense of shared responsibility. It's also important to establish expectations around response times for different communication methods, promoting timely and efficient interactions.

Furthermore, establishing a shared understanding of communication protocols, such as preferred language or tone, helps to maintain a professional and productive environment. This includes outlining the preferred method for addressing various issues, from minor questions to critical concerns.

Defining Roles and Responsibilities

Clearly defined roles and responsibilities are essential for preventing overlap and ensuring that everyone understands their contribution to the overall project or task. This involves outlining specific tasks, deadlines, and expectations for each team member. This clarity minimizes conflicts and promotes a sense of ownership and accountability among team members. Detailed job descriptions and task breakdowns ensure everyone is aware of their specific contributions.

Having well-defined roles and responsibilities also facilitates a smoother workflow, as team members know who to approach for specific tasks or information. This streamlined process minimizes confusion and maximizes efficiency.

Promoting Open and Honest Feedback

Creating a culture of open and honest feedback is vital for improving collaboration. Encouraging team members to provide constructive criticism and suggestions helps identify areas for improvement and fosters a more collaborative spirit. This includes establishing a safe space where team members feel comfortable sharing their opinions and concerns without fear of retribution.

Regular feedback sessions, both individual and group, can help track progress, identify potential roadblocks, and strengthen communication channels. Open dialogue also allows for the identification and resolution of potential conflicts before they escalate.

Fostering Trust and Respect

Trust and respect are cornerstones of any successful collaboration. Creating a supportive and inclusive environment where all team members feel valued and respected is paramount. This involves actively listening to diverse perspectives and fostering a sense of belonging among all participants. Team members who feel valued and respected are more likely to contribute their best work and actively participate in collaborative efforts.

Utilizing Collaborative Tools and Technologies

Leveraging appropriate collaborative tools and technologies can significantly enhance team performance. Project management software, shared documents, and online communication platforms can streamline workflow, improve communication, and facilitate real-time collaboration. These tools provide a centralized hub for information sharing and task management, ensuring everyone has access to the most up-to-date information.

Encouraging Active Participation and Engagement

Encouraging active participation and engagement is vital for a successful collaborative effort. Team members who feel included and valued are more likely to contribute their ideas and expertise. Actively seeking input from all team members, creating opportunities for brainstorming sessions, and facilitating group discussions can foster a sense of ownership and shared responsibility. This sense of shared ownership can lead to significant improvements in the team's overall output and morale.

Celebrating Successes and Learning from Setbacks

Recognizing and celebrating successes, both big and small, is essential for maintaining momentum and motivation. Acknowledging achievements reinforces positive behaviors and motivates team members to continue collaborating effectively. Similarly, constructive analysis of setbacks is crucial for identifying areas needing improvement and developing strategies for future success. Learning from failures enables the team to adapt and refine their collaborative processes over time.

- Jumeau numérique pour la gestion de flotte en temps réel

- Tours de contrôle de la chaîne d'approvisionnement : Améliorées par l'IA et l'analyse

- Transformer les opérations de la chaîne d'approvisionnement : utilisations pratiques de l'IA générative

- IA générative pour des stratégies d'engagement personnalisées des fournisseurs

- IA générative pour l'optimisation du réseau de la chaîne d'approvisionnement : des itinéraires plus intelligents

- Analyse prédictive pour optimiser la planification des effectifs pendant les périodes de forte activité

- Transformation des opérations de la chaîne d'approvisionnement : Cas d'utilisation pratiques de l'IA générative

- L'importance du nettoyage des données pour la précision et la fiabilité de la chaîne d'approvisionnement

- Le rôle des mégadonnées dans l'optimisation du réseau de la chaîne d'approvisionnement

- Pourquoi la traçabilité de la chaîne d'approvisionnement est-elle cruciale pour les entreprises d'aujourd'hui ?

- IA pour la gestion proactive des relations fournisseurs

- Analyse prédictive pour optimiser la planification des ventes et des opérations (S&OP) dans des environnements complexes