로봇 자동화를 통한 맞춤형 물류 서비스

Robotic Automation's Impact on Personalized Logistics

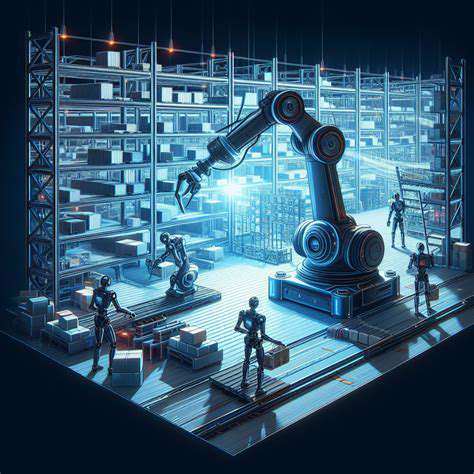

Robotic automation is revolutionizing the logistics industry, moving it beyond standardized processes and toward a future of personalized solutions. By integrating advanced robotics and AI, companies can now tailor their operations to individual customer needs, from customized packaging and delivery routes to optimized inventory management. This shift is not just about efficiency; it's about creating a more responsive and adaptable supply chain that anticipates and satisfies unique customer demands.

The ability to personalize logistics extends beyond simply adjusting delivery times. It encompasses the entire spectrum of the supply chain, from warehousing and order fulfillment to transportation and delivery. This personalized approach allows businesses to predict and react to potential disruptions, optimizing resource allocation and minimizing delays, ultimately leading to a more agile and customer-centric operation.

Tailoring Solutions for Specific Customer Needs

One of the key benefits of robotic automation in logistics is its ability to cater to the specific needs of different customer segments. Companies can now develop bespoke solutions for individual businesses or even individual customers, ensuring that the entire process aligns with their unique requirements. This might involve optimizing packing procedures for fragile items, adjusting delivery schedules for time-sensitive orders, or implementing specialized handling systems for particular product types. This level of customization is crucial in today's marketplace, where customers expect and demand a high degree of personalization.

Furthermore, robotic automation enables the creation of dynamic and adaptive supply chains. The system can adjust its processes in real-time based on fluctuating demand, order patterns, and unforeseen circumstances. This adaptability is vital for businesses aiming to provide a seamless and personalized experience to their customers, ensuring that orders are processed efficiently and delivered on time, regardless of the specifics.

Enhanced Efficiency and Reduced Costs

Beyond personalization, robotic automation significantly boosts efficiency and reduces costs within the logistics sector. Automated systems can handle repetitive tasks with precision and speed, freeing up human workers to focus on higher-level strategic initiatives. This increased efficiency translates to reduced operational expenses, faster order fulfillment, and ultimately, lower prices for consumers. By streamlining processes and minimizing errors, robotic automation contributes to a more cost-effective and profitable logistics operation.

Addressing the Challenges of Implementation

While the benefits of robotic automation in logistics are substantial, implementing these technologies comes with its own set of challenges. Businesses need to consider the potential costs associated with purchasing and maintaining robotic systems, along with the need for specialized training for employees to operate and manage these new technologies. Furthermore, integrating these systems into existing infrastructure and workflows requires careful planning and a clear understanding of the processes being automated. Overcoming these challenges is crucial for realizing the full potential of robotic automation in creating personalized logistics solutions.

Tailoring Warehouse Operations with Robotics

Optimizing Storage Space

Effective warehouse storage strategies are crucial for maximizing efficiency and minimizing operational costs. Careful layout planning, considering product dimensions and handling requirements, is paramount to optimizing storage space. This involves strategically utilizing different storage methods, such as pallet racking, shelving, and vertical storage systems, to ensure maximum capacity and accessibility. Implementing a robust inventory management system is also essential for tracking stock location and ensuring quick retrieval.

Employing automated storage and retrieval systems (AS/RS) can significantly enhance storage efficiency in high-volume warehouses. These systems, often incorporating robotics and advanced software, can automate the picking, packing, and storage processes, leading to considerable time savings and reduced labor costs. This technology is particularly beneficial in environments with stringent space constraints or high-velocity order fulfillment.

Streamlining Material Handling

Implementing efficient material handling systems is key to reducing operational bottlenecks and ensuring smooth order fulfillment. This encompasses the selection and strategic placement of forklifts, conveyors, and other equipment needed to transport goods within the warehouse. Proper training and adherence to safety protocols are critical for maximizing the effectiveness and minimizing the risk of accidents. Regular maintenance and preventative upkeep of equipment are essential to ensure optimal performance and prevent costly breakdowns.

Employing automated guided vehicles (AGVs) or other automated transport systems can greatly expedite the movement of goods throughout the warehouse, minimizing human intervention and increasing throughput. Using barcodes and RFID technology for real-time tracking of inventory location will further streamline processes and enable quicker order fulfillment.

Improving Order Fulfillment Accuracy

High accuracy in order fulfillment is crucial for building customer trust and satisfaction. Implementing standardized procedures, clear communication channels, and meticulous quality checks at each stage of the process are crucial for minimizing errors. Using barcode scanners or other automated identification systems for verification during picking and packing processes will ensure that orders are accurately fulfilled. Robust quality control measures, including double-checking and verification procedures, will also help maintain accuracy.

Investing in training programs for warehouse staff on order fulfillment procedures and quality control protocols will significantly enhance the accuracy of order processing. A commitment to meticulous record-keeping and data analysis will help identify potential bottlenecks and areas for improvement in the process.

Enhancing Technology Integration

Integrating technology into warehouse operations can provide significant benefits in terms of efficiency and productivity. Leveraging warehouse management systems (WMS) to track inventory, manage orders, and optimize workflows is key to achieving a seamless and streamlined operation. Utilizing real-time data analytics for insights into operational performance, identifying bottlenecks, and optimizing resource allocation is a valuable tool. This will also give a clear picture of the warehouse's efficiency and areas requiring improvement.

Adopting mobile devices and handheld scanners for real-time data capture and order processing can improve overall efficiency. Implementing an enterprise resource planning (ERP) system to integrate warehouse operations with other business functions will further streamline workflows and improve overall visibility.

Prioritizing Safety and Security

Prioritizing safety and security within warehouse operations is paramount for the protection of personnel, equipment, and inventory. Establishing clear safety protocols, providing comprehensive training, and enforcing compliance are essential for a safe working environment. Employing security measures such as surveillance cameras, access control systems, and security personnel will protect the warehouse from theft or damage.

Regular safety audits and risk assessments are essential for identifying potential hazards and implementing corrective measures. Promoting a culture of safety and security among all employees through communication and ongoing training is crucial for maintaining a secure and productive work environment.