利用數位雙生模擬建立彈性供應鏈

今日動態環境中供應鏈韌性的必要性

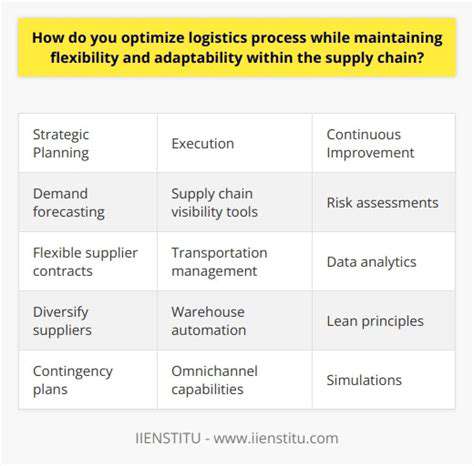

提升韌性

模擬中斷以提升準備度

了解模擬的重要性

模擬供應鏈中的中斷至關重要,有助於建立韌性。它使企業能夠預期潛在的問題

透過模擬優化庫存管理與物流

了解庫存優化的重要性

有效

實務應用與關鍵考量

實施強健的採購策略

建立彈性供應鏈的關鍵要素在於多元化採購策略。企業不應僅依賴單一供應商取得關鍵零組件,而應探索多個供應來源

THE END

More about 利用數位雙生模擬建立彈性供應鏈