Tác động của AI đến tốc độ ra quyết định trong chuỗi cung ứng

Chọn địa điểm tập luyện ngoài trời lý tưởng là rất quan trọng để tối đa hóa sự hưởng thụ và giảm thiểu sự phân tâm. Hãy xem xét các yếu tố như môi trường xung quanh...

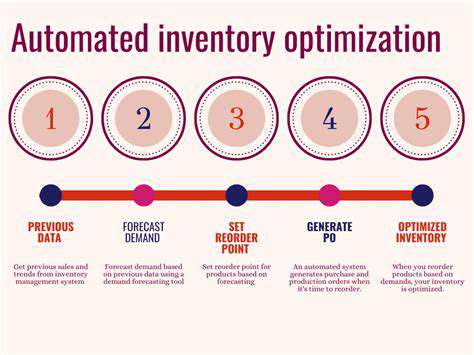

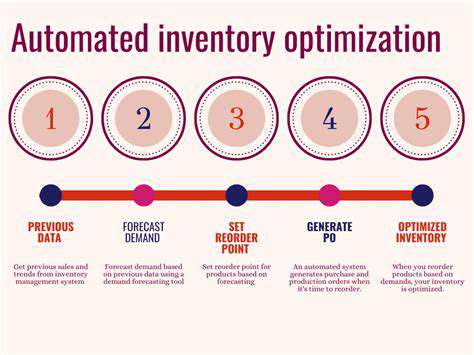

Tối ưu Quản lý Hàng tồn kho và Độ chính xác Dự báo Cầu

Hiểu về Quản lý Hàng tồn kho

More about Tác động của AI đến tốc độ ra quyết định trong chuỗi cung ứng

- Cách trang trí nhà cửa bằng đồ nội thất gỗ

- Những lời khuyên tốt nhất để bảo trì đồ gỗ teak

- Các loại gỗ phổ biến nhất cho đồ nội thất phong cách Mid-Century Modern

- Làm thế nào để tích hợp nội thất bằng gỗ vào không gian nhà bạn

- Cách tạo không gian phòng ngủ yên bình với đồ nội thất bằng gỗ

- Tại sao đồ nội thất bằng gỗ là khoản đầu tư bền vững cho ngôi nhà của bạn?

- Cách sử dụng đồ nội thất bằng gỗ để mang thiên nhiên vào nhà

- Bản sao kỹ thuật số cho khả năng phục hồi và mô phỏng mối đe dọa an ninh mạng của chuỗi cung ứng

- Tác động của máy tính lượng tử đối với công nghệ chuỗi cung ứng

- Công nghệ robot trong vận hành thương mại điện tử: Đáp ứng nhu cầu

- Giải pháp robot cho việc hoàn thành đơn hàng trong thương mại điện tử

- 5G cho phép kiểm tra cơ sở hạ tầng từ xa thời gian thực