How to choose the right wood finish for your wooden furniture

Traffic patterns matter more than most people realize. I've refinished enough dining chairs to know that armrests and front legs need extra protection. For outdoor projects, marine-grade varnishes with UV inhibitors prevent premature graying and deterioration.

Environmental Impact and Safety Considerations

The finishing room's ventilation isn't just about comfort - it's a health necessity. Traditional oil-based polyurethanes release strong fumes that can linger for weeks. Water-based finishes have revolutionized wood finishing, offering comparable protection without the noxious odors.

For children's furniture or kitchen items, food-safe finishes like pure tung oil or beeswax provide peace of mind. Always check the manufacturer's safety data sheets - some natural products still contain hazardous additives. Proper disposal of finishing rags is equally important to prevent spontaneous combustion.

Wood Type and its Implications for Finish Selection

Durability and Maintenance Requirements

Wood hardness varies dramatically across species. Janka hardness ratings provide objective comparisons - Brazilian walnut scores over 3,000, while white pine barely reaches 400. This difference determines whether a floor will dent under high heels or withstand decades of use.

Exotic woods often contain natural oils that complicate finishing. Teak and rosewood may require special cleaners to remove surface oils before finishing. Always test finishes on scrap pieces - some woods react unpredictably with certain finishes, causing discoloration or adhesion failure.

Environmental Impact and Sustainability

The lumber industry's environmental footprint concerns many woodworkers. FSC-certified woods ensure responsible forestry practices, while reclaimed lumber gives new life to old materials. Fast-growing bamboo offers an eco-friendly alternative, though its unique structure requires specialized finishing techniques.

Consider the entire lifecycle - locally sourced woods reduce transportation emissions, and proper finishing extends product lifespan. Some finishes themselves raise environmental concerns; citrus-based solvents provide a greener alternative to petroleum distillates.

Cost and Aesthetic Considerations

Budget often dictates material choices, but creative solutions can achieve high-end looks affordably. Poplar stained to resemble cherry or carefully selected pine can mimic expensive hardwoods. The right finish technique matters more than the wood's cost - a well-executed milk paint finish on pine can outshine poorly finished mahogany.

Grain patterns influence finishing decisions. Quarter-sawn oak's dramatic flecks demand different treatment than plain-sawn boards. Some woods like walnut develop richer patinas with oil finishes, while maple's tight grain shines under film-forming finishes.

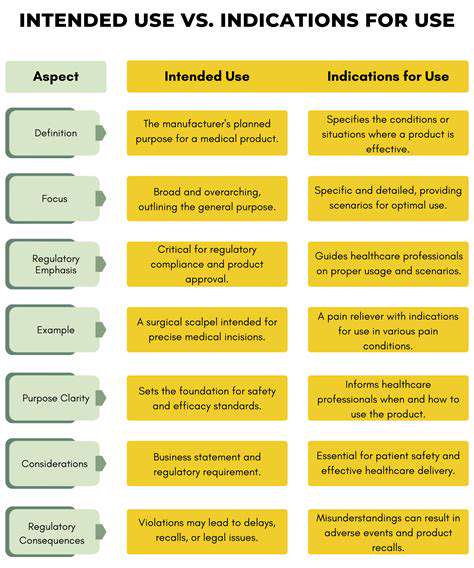

The Role of Intended Use in Finish Selection

Practical Considerations for Different Applications

Function dictates form in wood finishing. Bar tops need chemical-resistant epoxies, while musical instruments require thin, flexible finishes that don't dampen vibration. I once refinished a historic church pew - the finish needed to withstand centuries of use while maintaining its original character.

Outdoor furniture presents unique challenges. The finish must accommodate wood movement during seasonal changes while resisting moisture intrusion. Multiple thin coats outperform thick applications, which tend to crack as the wood expands and contracts.

Safety and Regulatory Compliance

Children's furniture regulations differ significantly from commercial requirements. Lead content restrictions and flammability standards vary by jurisdiction. Always verify compliance for products that will contact food or drinking water - salad bowls and cutting boards have specific finish requirements.

Commercial spaces often mandate fire-retardant finishes. These specialized products undergo rigorous testing and certification processes. Hospitals and schools frequently require finishes with antimicrobial properties, especially in high-touch areas.

Maintenance Expectations

Consider who will maintain the finish long-term. High-gloss finishes show every fingerprint, while satin finishes hide wear better. Some clients prefer easily renewable finishes like wax that they can maintain themselves, while others want durable coatings that require professional refinishing.

Restoration potential matters for antiques and heirlooms. Reversible finishes allow future conservators to remove layers without damaging the original wood. This philosophy guides many museum conservation approaches to finishing.

Thoughtful design enhances childhood development.

Comparing Popular Wood Finishes: Advantages and Disadvantages

Traditional Oil Finishes

Tung oil and linseed oil penetrate deeply, enhancing the wood's natural beauty. They're forgiving to apply - just wipe on, wait, and wipe off excess. However, they offer limited protection against spills and require frequent reapplication. Boiled linseed oil dries faster than raw but contains metallic dryers.

Danish oil combines oil with varnish for enhanced protection. It's my go-to for projects needing warmth and moderate durability. The hand-rubbed finish feels incredible but won't withstand heavy abuse.

Modern Water-Based Options

Water-based polyurethanes have improved dramatically. They dry crystal clear, unlike older formulations that could cloud certain woods. Application tips: use synthetic brushes to prevent bubbles, and maintain a wet edge to avoid lap marks. They're ideal for white or light-colored woods where yellowing would be problematic.

Acrylic-modified finishes offer the clarity of water-based products with enhanced durability. They're becoming popular for fine furniture where traditional looks meet modern performance requirements.

Specialty Finishes

Shellac, the original French polish, remains unmatched for repairability. Each layer melts into the previous one, allowing seamless spot repairs. However, alcohol spills will damage it instantly. It's perfect for heirloom pieces that will receive careful use.

Conversion varnish provides industrial-grade protection but requires professional application equipment. The two-part catalyzed finish creates an incredibly durable surface resistant to chemicals and abrasion.