Why hardwood is more durable than softwood for furniture

Microstructural Influences on Strength

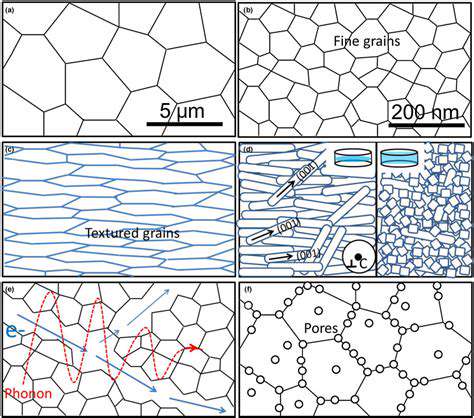

When examining materials, the microstructure—how grains and phases are arranged—plays a pivotal role in determining strength. The size and shape of grains directly influence how well a material resists deformation. Materials with smaller grains typically exhibit greater strength because the increased grain boundary area makes it harder for dislocations to move. This resistance to dislocation motion is a cornerstone of material strength.

Additionally, different phases like precipitates or inclusions can alter strength. These phases create barriers that dislocations must navigate, effectively strengthening the material. A deep understanding of these microstructural features is essential for predicting and fine-tuning mechanical properties.

Grain Boundaries and Their Impact

Grain boundaries, the interfaces between neighboring grains in polycrystalline materials, serve as obstacles for dislocations. These boundaries disrupt the movement of dislocations, which are defects in the crystal lattice that enable plastic deformation. A higher density of grain boundaries means more barriers for dislocations, resulting in enhanced strength. This principle is foundational in materials science and informs many strengthening strategies.

Key Strengthening Mechanisms

Several methods can strengthen materials. Reducing grain size, as previously mentioned, is one approach. Another is solid solution strengthening, where alloying elements introduce lattice strain fields that impede dislocation movement. Precipitation hardening, which involves dispersing fine precipitates throughout the material, also boosts strength significantly.

Dislocation Density and Material Strength

The number of dislocations in a material correlates with its strength. More dislocations create more obstacles, making it harder for the material to deform plastically and thereby increasing its strength. The behavior of dislocations under stress is central to understanding material failure, emphasizing the need to control dislocation density in material design.

Alloying Elements and Their Effects

Adding alloying elements can dramatically change a material's microstructure and strength. These elements can induce solid solution strengthening by distorting the lattice and hindering dislocation motion. The choice and concentration of alloying elements are critical for achieving the desired strength and mechanical properties. Selecting the right elements is a balancing act in material engineering.

Processing Parameters and Microstructure

Manufacturing processes have a profound impact on microstructure and strength. Heat treatments, for example, can modify grain size and distribution, altering strength. Deformation processes like cold working introduce dislocations and refine grain structure, leading to stronger materials. Mastering the relationship between processing and microstructure is key to optimizing performance.

Microstructure's Role in Failure

Microstructure doesn't just influence strength—it also dictates how materials fail. Features like crack initiation sites or stress concentration zones determine where and how failure occurs under load. Understanding these factors is vital for designing materials that resist failure in real-world applications, ensuring longevity and reliability.

Assess personal style to effectively choose a theme

Cost and Aesthetic Considerations: Balancing Quality and Value

Initial Investment Costs

Hardwood flooring, often seen as a premium option, varies in price based on wood species, grade, and finish. Exotic hardwoods like Brazilian cherry or ipe cost more than domestic options like maple or oak. Getting a detailed quote that includes materials, labor, and installation helps align the project with your budget.

Room size, installation complexity, and special requirements (e.g., stair treads or patterns) also affect costs. Research and planning ensure you strike the right balance between aesthetics and affordability.

Durability and Longevity

Hardwood flooring stands out for its durability. Properly installed and maintained, it can last decades, offering a strong return on investment by avoiding frequent replacements.

Hardwood's density and strength make it resistant to daily wear, especially in high-traffic areas like hallways and living rooms.

Maintenance and Upkeep

While durable, hardwood requires care to stay beautiful. Regular cleaning with hardwood-specific products and periodic refinishing protect its appearance over time. Knowing your wood's maintenance needs ensures its longevity.

Routine inspections catch early signs of damage, preventing costly repairs. Professional services can further extend your floor's life.

Aesthetic Appeal and Design Options

Hardwood offers endless design possibilities, from oak's warmth to exotic woods' bold looks. Colors, textures, and finishes let you match any style, from modern to classic.

Wood species, finishes (oil-based or water-based), and installation patterns (herringbone or planks) shape the final look, enhancing any room's ambiance.

Environmental Impact

Hardwood's environmental footprint depends on sourcing and production. Sustainable forestry practices minimize impact. Choosing certified, sustainably sourced wood is an eco-friendly option.

Value and Return on Investment

Hardwood's durability and beauty justify its initial cost. Over time, it adds value to your home, potentially increasing resale value. Weighing short-term costs against long-term benefits is key to smart decision-making.

- How to arrange wooden furniture in a small bedroom

- The process of crafting bespoke wooden furniture

- Best multi functional wooden furniture for compact spaces

- Best wooden furniture for apartments with small spaces

- How to blend wooden furniture with colorful décor

- Why wooden furniture can increase the value of your home

- How to enhance your living room with a wooden accent wall

- How to mix wooden furniture with metal elements in interior design

- How to use wood furniture to create a warm and inviting atmosphere

- Why solid wood furniture is the best investment for your home

- How to create a minimalist home with wooden furniture

- The most popular wood types for mid century modern furniture