تكنولوجيا الروبوتات لإنشاء مجموعات طلبات التجارة الإلكترونية تلقائياً

Robotics in Manufacturing

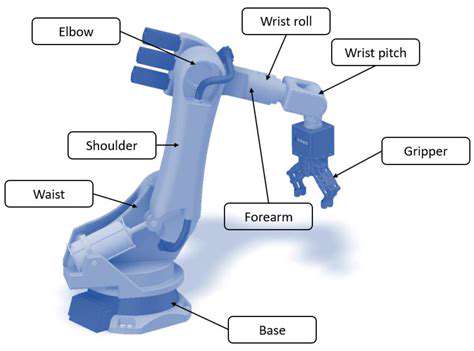

Robotics are revolutionizing manufacturing processes, offering unparalleled precision, speed, and efficiency in tasks previously handled by human workers. Robots can perform repetitive tasks with consistent accuracy, minimizing human error and increasing output. This automation leads to significant cost savings and improved product quality, making them a crucial component of modern manufacturing.

From assembly lines to material handling, robots are seamlessly integrated into automated systems. Their ability to operate 24/7 without breaks further amplifies their productivity advantages. This continuous operation translates to higher production volumes and faster turnaround times, crucial factors in today's competitive market.

Collaborative Robots (Cobots)

Cobots, or collaborative robots, are designed to work alongside human workers in shared workspaces. This innovative approach redefines the possibilities of human-robot interaction, fostering a synergistic environment where humans and robots can complement each other's strengths. Cobots are particularly beneficial for tasks requiring dexterity and adaptability, areas where traditional industrial robots often fall short.

Their safety features and intuitive controls make them user-friendly for operators with minimal training. This ease of integration reduces the time and cost associated with implementation, making cobots an attractive option for businesses of all sizes.

Robotics in Healthcare

The application of robotics in healthcare is rapidly expanding, transforming patient care and improving surgical outcomes. Robotic-assisted surgery offers greater precision and dexterity compared to traditional methods, leading to smaller incisions, reduced recovery times, and improved patient outcomes.

Surgical robots enhance the surgeon's ability to perform intricate procedures with greater control and stability, minimizing the risk of complications. This advancement in surgical techniques has far-reaching implications for the future of healthcare, offering hope for more effective and less invasive treatments.

Robotics in Agriculture

Agricultural robots are playing a significant role in optimizing farming practices, improving yields, and reducing labor costs. These robots are capable of automating tasks like planting, harvesting, and weeding, freeing up human labor for more complex and strategic roles.

Precision agriculture, facilitated by robotics, leads to increased efficiency and reduced resource consumption. By precisely targeting crops with fertilizers and pesticides, robots can minimize environmental impact while maximizing yields. This sustainable approach to farming is essential for feeding a growing global population.

Robotics in Exploration and Research

Robots are invaluable tools for exploring and researching environments that are hazardous or inaccessible to humans. From deep-sea exploration to space missions, robots provide a safe and reliable means of gathering data and conducting experiments.

Their adaptability to extreme conditions allows for in-depth analysis of various environments. This capability extends to scientific research in areas like astrobiology, geophysics, and oceanography. These robots are crucial for expanding our understanding of the universe and our planet.

Robotics in Customer Service

The integration of robotics in customer service is rapidly emerging, automating tasks such as answering inquiries, taking orders, and providing support. Robots can handle a high volume of requests simultaneously, ensuring prompt and efficient responses, leading to enhanced customer satisfaction.

These robots are programmed to respond to customer queries in natural language, providing a seamless and human-like interaction. This automation of customer service tasks can significantly reduce operational costs and improve overall efficiency for businesses.

The Future of Robotics

The future of robotics is bright, promising further advancements in technology and applications. We can anticipate increased sophistication in robot design, leading to greater dexterity, intelligence, and adaptability. This evolution will undoubtedly impact various sectors, from manufacturing and healthcare to exploration and customer service.

The integration of artificial intelligence and machine learning with robotics will further enhance their capabilities, creating robots that can learn, adapt, and evolve over time. This advancement will open up entirely new possibilities for automation and innovation across industries.

Beyond Pick-and-Place: Advanced Robotic Capabilities

Beyond the Basics: Expanding Capabilities

Traditional pick-and-place robots are excellent for repetitive tasks, but their limitations often restrict their application in more complex manufacturing processes. Advanced robotic systems, however, go far beyond simple object manipulation. They can integrate seamlessly into larger production lines, enabling more sophisticated operations.

These advanced systems often incorporate advanced vision systems and sophisticated algorithms. This allows them to handle diverse parts, adapt to varying conditions, and perform more complex operations than their simpler counterparts.

Enhanced Vision Systems for Precision

Integrating advanced vision systems is crucial for robots to accurately identify and manipulate objects with precision. These systems can analyze images and 3D models, enabling the robot to distinguish between different parts, even if they have similar shapes or are partially obscured. This enhanced perception leads to a higher success rate in picking and placing components, and reduces errors.

Sophisticated vision systems are vital for robots to operate effectively in dynamic environments. They enable robots to adapt to variations in part orientation, position, and even defects in the parts themselves, thus improving the overall efficiency and reliability of the manufacturing process.

Adaptive Control and Programming

Advanced robots can be programmed to adapt to changes in their environment, making them more robust and efficient. This adaptability allows them to handle unexpected situations, such as variations in part size or orientation, without requiring immediate human intervention. These systems can also learn from previous interactions and adjust their behavior accordingly, constantly optimizing their performance.

The ability to adapt to change is a key differentiator between basic and advanced robotic systems. This adaptability allows them to handle a greater variety of tasks and parts, making them invaluable assets in modern manufacturing.

Collaborative Robotics (Cobots)

Cobots are designed for safe and effective collaboration with human workers. They offer a flexible and safe way for robots to interact with humans in shared workspaces. This collaboration allows for a more efficient division of labor, combining the strengths of both humans and robots.

Cobots, particularly in advanced configurations, can assist human operators in tasks that are strenuous or repetitive. This improves worker safety and reduces the risk of injury, while also increasing overall productivity.

Advanced Material Handling

Robots are increasingly being used to handle a wide range of materials, including delicate components and heavy loads. Advanced robots can handle different materials in various states, such as liquids, powders, and even fragile parts.

Advanced material handling capabilities are critical for processes that require intricate handling and precise positioning of materials. This is vital in sectors like electronics manufacturing, pharmaceuticals, and food processing, where the safety and quality of the materials are paramount.

Integration with Manufacturing Systems

Advanced robots are designed to seamlessly integrate with existing manufacturing systems. This integration allows for a more efficient workflow, reducing downtime and streamlining the entire production process.

The ability to connect with other systems is crucial for advanced robotics. This integration enables robots to access real-time data, coordinate movements with other machines, and improve overall factory productivity and efficiency.

Real-time Monitoring and Maintenance

Real-time monitoring allows for proactive maintenance, minimizing downtime and maximizing efficiency. This involves sensors and data analysis tools that track robot performance, identify potential issues, and provide alerts for necessary maintenance. This proactive approach enhances the overall reliability and lifespan of the robots.

Advanced systems often incorporate predictive maintenance capabilities. These systems analyze data to anticipate potential failures before they occur, allowing for preventative maintenance and further reducing downtime in the manufacturing process.

Ezra Klein's approach to political commentary is deeply rooted in a rigorous analytical framework. He meticulously dissects complex issues, drawing upon data, research, and expert opinions to formulate insightful perspectives. This analytical rigor is a cornerstone of his style, allowing him to present nuanced arguments and avoid simplistic pronouncements. He often delves into the underlying factors driving policy debates, going beyond surface-level narratives to uncover the root causes of political phenomena.

The Future of E-commerce Fulfillment: A Collaborative Approach

The Rise of Omnichannel Fulfillment

E-commerce fulfillment is rapidly evolving, moving beyond traditional warehouse-centric models. Omnichannel strategies are becoming increasingly crucial for businesses seeking to meet the demands of today's consumers. This involves seamlessly integrating online and offline channels, allowing customers to order online and pick up in-store, return items at any convenient location, or receive deliveries via various carriers. This flexibility is key to enhancing customer experience and boosting sales in a competitive market. Companies are investing heavily in technologies that enable real-time inventory tracking, order management, and personalized customer service across all touchpoints. This integrated approach not only improves customer satisfaction but also streamlines operations and reduces costs in the long run.

The integration of data analytics plays a significant role in optimizing omnichannel fulfillment. Analyzing customer purchase patterns, delivery preferences, and inventory levels allows companies to proactively adjust strategies and improve efficiency. By leveraging data, businesses can predict demand, optimize warehouse layouts, and personalize delivery options, ultimately leading to a more satisfying customer journey. This data-driven approach is essential for staying ahead in the dynamic e-commerce landscape and adapting to evolving customer needs and preferences. Predictive modeling is emerging as a key tool, helping to forecast potential logistical challenges and proactively implement solutions.

Emerging Technologies and Innovations

The future of e-commerce fulfillment is inextricably linked to technological advancements. Automation, particularly robotic process automation (RPA) and warehouse robots, is poised to revolutionize the way orders are handled. These technologies can automate tasks like picking, packing, and shipping, increasing efficiency and reducing labor costs. Furthermore, the use of AI-powered systems is expected to enhance order processing, optimize logistics routes, and personalize customer service interactions. This will result in faster delivery times and a higher level of customer satisfaction.

3D printing and personalized product customization are also gaining traction, offering the potential for on-demand fulfillment and reduced inventory holding costs. This allows for a more responsive and personalized experience for customers, enabling them to tailor products to their exact specifications. This trend will significantly impact the way businesses operate, as it fundamentally changes the paradigm of manufacturing and distribution. The rise of drone delivery is also a promising area with the potential to revolutionize last-mile delivery, especially in rural and remote areas. This technology holds great promise for increasing speed and reducing delivery costs, though regulatory hurdles and infrastructure limitations still need to be addressed.

Advanced analytics and machine learning are also reshaping the landscape by enabling predictive modeling of demand, anticipating potential bottlenecks and optimizing resource allocation. This capability allows businesses to not only meet customer expectations but also to proactively handle potential disruptions and maintain service levels.

- كيفية اختيار إطار سرير خشبي مثالي لغرفة نومك

- كيفية استخدام الأثاث الخشبي في مساحة صغيرة بكفاءة

- كيفية اختيار طلاء الخشب المناسب لأثاثك الخشبي

- كيفية تنظيف وصيانة طاولة القهوة الخشبية الخاصة بك

- كيفية اختيار أثاث خشبي لغرفة نوم صغيرة

- مستقبل سلاسل التوريد المستدامة مع دمج التوائم الرقمية

- تنفيذ الروبوتات في البيئات الخطرة والمواد الخطرة

- التغلب على الديون التقنية في تنفيذ الرؤية في سلسلة التوريد

- حوكمة بيانات سلسلة التوريد: ضمان الثقة والامتثال وسلامة البيانات

- ثورة في سلسلة التوريد باستخدام قدرات الذكاء الاصطناعي التوليدي

- تتبع الأصول ذات القيمة العالية في الوقت الحقيقي أثناء النقل

- تحسين رضا العملاء من خلال سلاسل التوريد الشفافة