De réactif à prédictif : L'évolution de la visibilité de la chaîne d'approvisionnement

The Shifting Sands of Supply Chain Management

Global Disruptions and Resilience

The global supply chain has undergone a period of unprecedented disruption, marked by factors like the COVID-19 pandemic, geopolitical tensions, and extreme weather events. These disruptions have exposed vulnerabilities and highlighted the need for greater resilience in modern supply chain management. Companies are now forced to re-evaluate their strategies and prioritize diversification of suppliers and production locations. This increased complexity necessitates a more agile and adaptable approach to managing risks.

The pandemic's impact was particularly significant, leading to widespread shortages of essential goods and services. Supply chain bottlenecks and shipping delays became commonplace, causing significant financial losses and impacting consumer confidence. This experience has spurred a fundamental shift in how companies approach supply chain risk management, emphasizing proactive measures to mitigate future disruptions.

Technological Advancements and Automation

Technological advancements are revolutionizing the supply chain landscape. From sophisticated data analytics to automation technologies like robotics and AI, these tools are transforming how goods are sourced, manufactured, and delivered. The integration of these technologies promises greater efficiency, transparency, and responsiveness within the supply chain. This allows companies to track inventory in real-time, optimize logistics, and predict potential disruptions more effectively.

Automation is playing a crucial role in streamlining processes. Automated warehousing, robotic picking, and AI-powered predictive maintenance systems are reducing labor costs, improving accuracy, and increasing output. These advancements not only increase efficiency but also enhance safety by minimizing human error in critical operations.

Sustainability and Ethical Considerations

Sustainability is no longer a peripheral concern but a core element of modern supply chain management. Companies are increasingly recognizing the importance of environmentally responsible practices, minimizing their carbon footprint, and ensuring ethical labor standards throughout their supply chains. This shift is driven by consumer demand for sustainable products and the growing awareness of environmental issues.

Ethical considerations are also gaining prominence. Companies are scrutinizing their supplier networks to ensure fair labor practices, responsible sourcing, and adherence to human rights standards. Transparency and accountability throughout the supply chain are critical to building trust and maintaining a positive brand image.

The Rise of Decentralized Networks

The trend toward decentralized supply chains is gaining momentum. Companies are exploring alternative models that distribute manufacturing and distribution centers across various geographical locations. This strategy aims to enhance resilience by reducing reliance on single points of failure and promoting local production to mitigate risks associated with global events.

This approach is especially beneficial for companies operating in regions with political instability or economic volatility. The benefits also extend to faster delivery times and reduced transportation costs. By diversifying production and distribution hubs, companies are bolstering their ability to adapt to unforeseen circumstances.

Adapting to Evolving Consumer Demands

Consumer demands are constantly evolving, with a growing emphasis on customization, personalization, and speed of delivery. Companies must adapt their supply chains to meet these evolving expectations. This necessitates increased flexibility and responsiveness in order to cater to diverse preferences and demands.

The rise of e-commerce and online shopping has further accelerated this trend. Companies must now streamline their operations to accommodate faster order fulfillment and flexible delivery options.

The Future of Supply Chain Management

The future of supply chain management is characterized by a dynamic interplay of technology, sustainability, and responsiveness. Companies are expected to continue embracing innovation to enhance efficiency, resilience, and sustainability. Adaptability and flexibility will be critical for navigating the challenges and opportunities in the evolving landscape.

Continuous improvement, collaboration, and a proactive approach to risk management are essential components in building a robust and future-proof supply chain.

The Role of Technology in Predictive Visibility

The Evolution of Predictive Technologies

Predictive technologies have undergone a significant transformation over the past few decades, moving from rudimentary statistical models to sophisticated algorithms capable of analyzing vast datasets and generating highly accurate predictions. This evolution has been fueled by advancements in computing power, data storage capacity, and machine learning techniques. The ability to process and interpret complex data has opened doors to unprecedented levels of insight, enabling organizations to anticipate trends and make proactive decisions.

Data Collection and Analysis in Predictive Modeling

A crucial aspect of predictive technology lies in the collection and analysis of data. Effective predictive models require access to high-quality, relevant data, which can encompass everything from customer demographics and purchasing history to market trends and economic indicators. Analyzing this data through sophisticated statistical methods and machine learning algorithms allows for the identification of patterns and relationships that would otherwise be hidden. This process is essential for developing accurate predictive models.

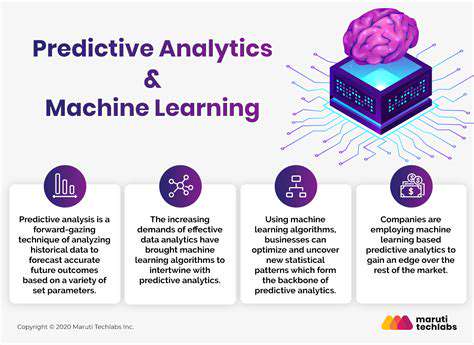

Machine Learning Algorithms in Predictive Modeling

Machine learning algorithms are at the heart of many modern predictive technologies. These algorithms learn from historical data to identify patterns and relationships that can be used to predict future outcomes. Different types of machine learning algorithms, such as regression, classification, and clustering, are employed depending on the specific prediction task. The selection of the appropriate algorithm is critical to ensure the accuracy and reliability of the predictive model. Furthermore, the ongoing refinement of these algorithms is constantly pushing the boundaries of what's possible in terms of prediction accuracy.

Applications of Predictive Technologies Across Industries

The applications of predictive technologies are diverse and span numerous industries. In finance, predictive models can be used to assess credit risk and identify potential fraud. In healthcare, predictive models can help identify patients at risk for certain diseases and personalize treatment plans. In marketing, predictive models can help target customers more effectively and personalize their experiences. Across industries, predictive technology empowers businesses to make more informed decisions and optimize their operations.

The Importance of Accuracy and Reliability in Predictive Models

Accuracy and reliability are paramount when developing predictive models. Inaccurate predictions can lead to costly mistakes, and unreliable models can erode trust in the technology. Rigorous testing and validation procedures are essential to ensure the accuracy and reliability of predictive models. Careful consideration must be given to factors such as data quality, model complexity, and the specific prediction task. Continuous monitoring and refinement of the models are also crucial to maintaining their effectiveness over time.

Ethical Considerations and Future Trends in Predictive Technology

The increasing use of predictive technologies raises significant ethical considerations, particularly regarding privacy and bias. It's crucial to ensure that these technologies are used responsibly and ethically, avoiding the perpetuation of existing biases in data and respecting the privacy of individuals. The future of predictive technology likely holds even more sophisticated algorithms and more complex applications. Further research and development are likely to uncover new opportunities and challenges in this exciting and rapidly evolving field.

The Benefits of a Predictive Approach

Predictive Maintenance for Enhanced Efficiency

A predictive approach to supply chain management, moving beyond simply reacting to problems, allows for proactive maintenance of equipment and processes. This proactive stance is crucial for avoiding costly downtime and ensuring consistent performance. By analyzing historical data, current conditions, and potential future trends, predictive maintenance can pinpoint potential equipment failures before they occur. This allows for scheduled maintenance interventions, minimizing disruptions and maximizing operational efficiency. Predictive maintenance strategies, when implemented effectively, can significantly reduce unplanned downtime, leading to substantial cost savings and improved overall operational performance.

Predictive maintenance goes beyond simply identifying potential issues. It also allows for optimization of maintenance schedules, ensuring that resources are allocated effectively and efficiently. By forecasting equipment needs, companies can avoid overspending on unnecessary maintenance or under-preparing for critical repairs, leading to a more streamlined and cost-effective maintenance process. This proactive approach to maintenance is a cornerstone of a truly predictive supply chain, enabling businesses to anticipate and mitigate risks before they impact operations.

Demand Forecasting for Optimized Inventory

Accurate demand forecasting is essential for effective inventory management. In a reactive supply chain, companies often struggle to maintain optimal inventory levels, leading to either stockouts or excessive inventory holding costs. Predictive techniques, however, allow businesses to anticipate future demand with greater accuracy, enabling them to optimize inventory levels and reduce waste. By analyzing historical sales data, market trends, and external factors, companies can create more precise demand forecasts, ensuring they have the right amount of inventory on hand to meet customer needs without overstocking or understocking.

The benefits extend beyond simple inventory management. Accurate demand forecasting allows for more effective production planning. By understanding future demand, companies can adjust production schedules to align with projected needs, minimizing waste and maximizing efficiency. This alignment between demand and production is crucial for a smooth and efficient supply chain, ensuring that products are available when and where they are needed, ultimately enhancing customer satisfaction.

Real-Time Visibility and Adaptability

A predictive supply chain relies heavily on real-time visibility into all aspects of the operation. By tracking shipments, inventory levels, and other key metrics, companies gain a comprehensive understanding of the current state of their supply chain. This real-time visibility provides the crucial data needed for predictive analytics to forecast potential issues and opportunities. The ability to swiftly adapt to changes in supply and demand becomes a significant advantage, allowing for proactive adjustments to mitigate disruptions and capitalize on emerging opportunities.

This real-time data allows for rapid response to unexpected events. Sudden changes in demand, supplier issues, or natural disasters can be quickly identified and addressed, minimizing potential disruptions to the supply chain. The ability to adapt in real-time is paramount in a predictive approach, enabling businesses to navigate unforeseen circumstances and maintain operational continuity. With the ability to see and react to changes as they happen, companies can ensure that their supply chains remain resilient and adaptable in the face of challenges.

- Construire la Résilience : Comment des Relations Solides Offrent un Soutien en Temps Difficiles

- Le Guide Ultime pour Concevoir un Espace de Travail Productif

- Comment créer un look sophistiqué avec des meubles en bois foncé

- Comment créer une ambiance rustique avec des meubles en bois

- Pourquoi le bois dur est plus durable que le bois tendre pour le mobilier

- Comment associer des meubles en bois à des couleurs et des motifs audacieux ?

- Comment créer un environnement de chambre apaisant avec du mobilier en bois

- Meubles en bois les plus performants pour améliorer votre espace de vie

- Protocoles de sécurité homme-robot dans les environnements logistiques

- IA pour l'automatisation du filtrage de conformité commerciale

- Robotique en tant que service (RaaS) : Solutions d'automatisation flexibles

- Traitement du langage naturel pour l'analyse des rapports et des tendances du secteur