Dados de Logística em Tempo Real: Otimizando Entregas e Rotas

Otimizando Rotas e Horários de Entrega

Estratégias de Planejamento de Rotas

Otimização eficaz de rotas de entrega envolve

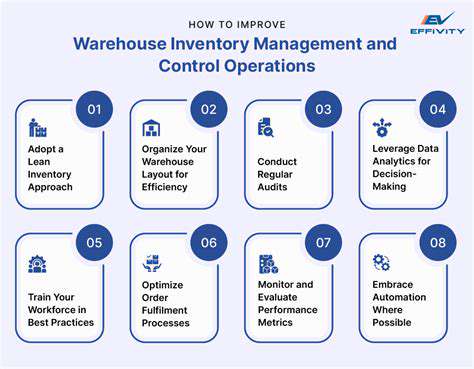

Melhoria das Operações de Armazém e Gestão de Inventário

Otimização dos Processos de Receção

Processos de receção eficientes são cruciais para operações de armazém fluidas e

THE END

More about Dados de Logística em Tempo Real: Otimizando Entregas e Rotas

- Como fazer seus móveis de madeira durarem mais com manutenção regular

- Os benefícios de usar acabamentos de madeira natural em seus móveis

- Por que a mobília de madeira maciça é ideal para interiores com inspiração vintage

- Como escolher móveis de madeira que combinam com seu estilo de vida

- Como criar um espaço de estar acolhedor com móveis de madeira

- Melhores dicas para projetar sua casa com móveis de madeira

- Melhores peças de madeira para melhorar seu espaço de estar

- Como fazer móveis de madeira sobressair em uma sala de estar moderna

- Como misturar móveis de madeira com detalhes metálicos modernos

- Revolucionando o Planejamento da Cadeia de Suprimentos com IA Generativa

- Transformando as Operações da Cadeia de Suprimentos: Usos Práticos de IA Generativa

- 5G para permitir inspeções remotas em tempo real de infraestruturas