Robotics for automated palletizing of mixed goods

Introduction to Automated Palletizing Systems

Understanding the Fundamentals of Automated Palletizing

Automated palletizing systems are revolutionizing warehousing and logistics, offering significant advantages over manual processes. These systems are designed to efficiently and accurately stack products onto pallets, streamlining the entire order fulfillment process. By automating this critical step, businesses can significantly reduce labor costs and improve overall operational efficiency. This automation leads to faster throughput and reduced errors, ultimately boosting productivity. Furthermore, automated palletizing systems minimize the risk of human error associated with manual handling, ensuring consistency and accuracy in every pallet.

The fundamental principle behind automated palletizing systems centers on the precise and repeatable movement of materials. This precision is crucial for maintaining product integrity, preventing damage, and ensuring the safe and secure transport of goods. The integration of advanced sensors and robotic arms plays a critical role in achieving this level of precision and repeatability. The technology is constantly evolving, with new innovations leading to even greater efficiency and accuracy.

Types of Automated Palletizing Systems

Several types of automated palletizing systems are available, each tailored to specific needs and applications. These systems vary in complexity and capabilities, ranging from simple, fixed-position systems to more sophisticated, flexible, and adaptable solutions. Understanding the different types is essential for selecting the most suitable system to meet the unique demands of a particular business. Consideration of factors like throughput requirements, product size, and pallet configurations is crucial in the selection process.

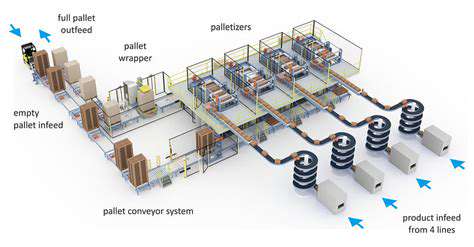

One common type is the robotic palletizing system, which uses robotic arms to handle products and place them on pallets. These systems are highly versatile and can handle a variety of products and pallet types. Another type is the conveyor-based system, which utilizes a conveyor belt to transport items to the palletizing area. These systems are generally more suitable for repetitive and standardized operations.

Benefits of Automated Palletizing

Implementing automated palletizing systems yields a wide range of benefits for businesses. Reduced labor costs are a significant advantage, freeing up human workers for more valuable tasks. Increased productivity is another key benefit, as automated systems can handle large volumes of goods much faster than manual processes. Consistent quality and accuracy are guaranteed, leading to fewer errors and a higher standard of product handling. Improved safety is another significant advantage due to the reduction of manual handling and the elimination of repetitive strain injuries.

In addition to these direct benefits, automated palletizing systems contribute to a more streamlined and efficient warehouse operation. This, in turn, leads to reduced storage space requirements, improved order fulfillment times, and ultimately, increased customer satisfaction. Overall, the implementation of these systems significantly improves the entire supply chain.

Key Considerations in System Selection

Choosing the right automated palletizing system requires careful consideration of several factors. Throughput requirements, product characteristics, and pallet dimensions are critical to evaluating the system's suitability for a particular operation. Careful assessment of the existing infrastructure and any potential modifications required is crucial. The cost of the system, including installation, maintenance, and training, should also be factored into the decision-making process. This careful evaluation ensures a system that effectively meets the unique needs of the business.

Integration with existing warehouse management systems (WMS) and other automation technologies should also be considered. A smooth integration will result in better data flow, improved visibility, and enhanced efficiency across the entire supply chain. This careful planning ensures a long-term, effective investment in automation.

Maintenance and Support for Optimal Performance

Regular maintenance and support are essential for ensuring the optimal performance of automated palletizing systems. A comprehensive maintenance schedule, developed in consultation with the equipment provider, is critical for minimizing downtime and maximizing uptime. This proactive approach prevents costly equipment failures and ensures that the system continues to operate at peak efficiency.

Training personnel on the proper operation and maintenance procedures is vital for ensuring the system's longevity and reliability. Regular inspections and prompt resolution of any issues will significantly extend the lifespan of the equipment. By prioritizing preventative maintenance, companies can avoid costly repairs and ensure that the automated palletizing system remains a valuable asset for years to come.

Challenges in Palletizing Mixed Goods

Choosing the Right Palletizing Robot

Selecting the appropriate palletizing robot for mixed goods presents a significant challenge. Different robots excel in different scenarios, and the optimal choice hinges on factors like the variety and size of the products, the frequency of order changes, and the desired throughput. Consideration must be given to the robot's payload capacity, reach, and dexterity to ensure efficient handling of diverse items without compromising safety or damaging the goods. This careful selection process is crucial to optimizing the palletizing process and maximizing operational efficiency.

Furthermore, the integration of the chosen robot with existing warehouse infrastructure and software systems is critical. A seamless integration minimizes downtime and ensures smooth data flow. This includes considerations for the robot's communication protocols, the warehouse management system (WMS), and any necessary auxiliary equipment. Failing to address these integration complexities can lead to significant inefficiencies and delays in the palletizing process for mixed goods.

Handling Variability in Product Sizes and Shapes

The inherent variability in product sizes and shapes presents a major hurdle in automated palletizing of mixed goods. Robots need to be programmed to accommodate a diverse range of items, requiring sophisticated algorithms and adaptable gripping mechanisms. This adaptability demands advanced programming and machine learning capabilities, allowing the robot to adjust to different item orientations and dimensions without compromising palletizing accuracy or safety.

Ensuring that the robot can reliably and safely handle various product shapes and sizes is paramount. This includes accommodating different heights, widths, and weights. Improper handling can lead to damage, misplaced items, and even safety hazards. Robust sensor systems and advanced control algorithms are essential for accurate and consistent palletizing in the face of this variability.

The intricate nature of mixed goods palletizing requires a high degree of flexibility in the robot's programming. This flexibility allows for efficient and accurate handling of diverse product combinations. Furthermore, the robot must be capable of identifying and correctly placing each item in the correct location on the pallet to avoid errors and ensure the integrity of the entire palletizing operation. These factors highlight the importance of sophisticated programming and robust sensor systems.

In addition to the above, the robot's adaptability to unforeseen variations in product presentation is crucial. Flexibility ensures that the robot can handle situations where products might not be consistently placed or oriented. This adaptive ability enhances the robot's efficiency and reliability in a dynamic warehousing environment.

Addressing these challenges requires an investment in advanced robotics and software solutions, but the benefits in terms of increased efficiency and reduced errors are substantial.

Robust error handling and a feedback loop are critical to maintaining the accuracy of the palletizing process. The ability to detect errors and adjust accordingly is essential for ensuring high quality and reliable palletizing operations.

Implementing and Optimizing Automated Palletizing Systems

Choosing the Right Palletizing System

Selecting the appropriate automated palletizing system is crucial for maximizing efficiency and minimizing downtime. Factors like the type of product being handled, the volume of pallets needed, and the existing warehouse layout all play a significant role in the decision-making process. Careful consideration must be given to the size, weight, and shape of the product to ensure the system is capable of handling it safely and accurately, preventing damage to the goods or the palletizing equipment itself. Detailed analysis of current and projected throughput needs is essential for a long-term solution that scales with business growth.

Evaluating different types of palletizing robots, from robotic arms to specialized systems designed for specific industries, is critical. This evaluation should include factors such as payload capacity, speed, and accuracy. Additionally, the cost of the system, including installation, maintenance, and potential future upgrades, should be part of the comprehensive assessment. A well-chosen system will not just meet current needs, but also be adaptable to future demands and changes in the production line.

Implementing the Automated Palletizing System

Careful planning and execution are critical during the implementation phase. This involves a phased approach, starting with a thorough assessment of the current workflow and identifying areas for improvement. Integrating the new palletizing system with existing warehouse management systems (WMS) is essential to ensure seamless data flow and efficient tracking of pallets. Training personnel on the operation and maintenance of the new system is critical for smooth day-to-day functioning. This should include both basic operation and advanced troubleshooting procedures to ensure rapid response to any potential issues.

Ensuring proper safety protocols and procedures is paramount. This includes creating a dedicated safety zone around the palletizing equipment and implementing strict adherence to safety guidelines. Regular safety checks and maintenance of the system are essential to prevent accidents and ensure the longevity of the equipment. Effective communication between the robotics team, warehouse staff, and other relevant personnel is crucial for a smooth transition.

Optimizing Palletizing System Performance

Continuous monitoring and analysis are essential for achieving peak performance from an automated palletizing system. Real-time data on system efficiency, such as throughput rates and downtime, should be collected and analyzed regularly to identify bottlenecks and areas for improvement. Data analysis can help pinpoint potential issues, such as equipment malfunctions, operator errors, or material handling problems, allowing for proactive solutions and minimizing unnecessary delays.

Regular maintenance and calibration are critical to maintaining optimal performance. This includes routine checks of robotic arm movements, conveyor belt operation, and other components. Proactive maintenance schedules are essential to preventing significant breakdowns and ensuring the system operates at peak efficiency. Regular performance evaluations will help to identify and resolve potential issues before they impact production output.

Ensuring System Scalability and Adaptability

The chosen palletizing system should be designed with future scalability in mind. As production volumes increase, the system should be able to handle the increased demand without significant modifications or upgrades. This includes considering factors like future expansions, changes in product types, and potential integration with other automated systems. A modular design can allow for future expansion, adding new functions or capabilities to the existing system as business needs change.

Adapting to changing product demands and improving the flexibility of the palletizing system is a key aspect of long-term optimization. The ability to quickly reconfigure the system for different product types or sizes is essential for a dynamic and responsive production line. This includes the ability to adjust the system's parameters and programming based on real-time changes in product specifications or production needs. This adaptability is crucial for ensuring efficient and cost-effective operation in a constantly evolving market.

Future Trends and Considerations

Emerging Technologies and Their Impact

The rapid advancement of artificial intelligence (AI) is poised to revolutionize various sectors, from healthcare to finance. AI-powered tools are already demonstrating impressive capabilities in automating tasks, improving efficiency, and enabling data-driven decision-making. This burgeoning technology promises significant improvements in diagnosis and treatment in healthcare, leading to more personalized and effective patient care.

Furthermore, the increasing accessibility of big data and the development of sophisticated algorithms are enabling businesses to gain deeper insights into consumer behavior and market trends. This allows for more targeted marketing campaigns, optimized product development, and improved customer experience. The integration of AI into everyday life is transforming our interactions with technology, promising a more intuitive and responsive user experience.

Sustainability and Environmental Concerns

The growing awareness of environmental issues is driving a shift towards sustainable practices in various industries. Companies are increasingly prioritizing eco-friendly production methods, reducing waste, and implementing sustainable supply chains. This trend is not only beneficial for the environment but also fosters a more responsible and ethical business model.

Implementing sustainable practices is becoming a crucial factor in attracting investors and maintaining a positive brand image. Consumers are increasingly demanding environmentally friendly products and services, and businesses that embrace sustainability are likely to gain a competitive edge in the market.

Moreover, the development of renewable energy sources and smart grids is crucial for reducing our reliance on fossil fuels and mitigating climate change. This transition requires significant investments and collaborations across industries, but the potential long-term benefits are substantial.

Global Economic Shifts and Market Dynamics

The interconnected nature of the global economy is leading to significant shifts in market dynamics. The rise of emerging economies and the changing geopolitical landscape are creating new opportunities and challenges for businesses worldwide. Companies must adapt to these evolving conditions to remain competitive and profitable.

Understanding and responding to these shifts is critical to navigating the complexities of the modern marketplace. International trade agreements, fluctuating exchange rates, and political instability can all have a profound impact on businesses, requiring careful risk assessment and proactive strategies.

Furthermore, the increasing prevalence of globalization is fostering cultural exchange and collaboration, but also creating challenges related to cultural sensitivity and diversity management. Navigating these complexities requires sensitivity and adaptability from businesses operating in a globalized world.

Ethical Considerations and Societal Impacts

The rapid advancement of technology raises crucial ethical considerations. Issues such as data privacy, algorithmic bias, and the potential for misuse of AI require careful attention and proactive measures to mitigate risks. Addressing these issues is essential to ensure that technological advancements benefit society as a whole, rather than exacerbating existing inequalities.

Furthermore, the impact of automation on employment is a significant concern. As machines take over tasks previously performed by humans, there is a need for retraining and upskilling programs to prepare the workforce for the future of work. This transition requires a collaborative effort from governments, businesses, and educational institutions.

The Role of Human Capital and Innovation

In an increasingly competitive landscape, the importance of human capital and innovation cannot be overstated. Attracting, retaining, and developing skilled employees is crucial for driving growth and success. Investing in employee training and development programs, fostering a culture of innovation, and encouraging collaboration are key strategies.

Companies that prioritize human capital and innovation are better positioned to adapt to change and seize new opportunities. Embracing a culture of continuous learning and experimentation is critical for staying ahead of the curve and achieving long-term success in the face of future uncertainties.

- The best wood types for furniture that lasts

- The best wooden furniture for enhancing your home’s curb appeal

- How to choose a wooden chair for maximum comfort

- How to incorporate wood furniture into your minimalist home

- How to combine wooden furniture with vintage decor

- AI Powered Visual Inspection for Quality Control

- Navigating the Tech Stack: Choosing the Right Supply Chain Solutions for Your Business

- Real Time Insights: Digital Twins for Proactive Supply Chain Management

- Revolutionizing Supply Chain Planning with Generative AI Capabilities

- Generative AI for Supply Chain Risk Assessment and Mitigation

- Digital Twin for Real Time Energy Management in Warehouses

- Digital Twin for Automated Decision Making in Supply Chain